Preamble

This is an example of previous post Reverse Problem Mapping and AI-Augmented Discovery for Untethered Ideas

Thanks for reading! Subscribe for free to receive new posts and support my work.

Born out of a “Reverse Problem Mapping” session and AI-augmented discovery, the Mega Evaporator concept began as an open-ended attempt to find a worthy problem for an audacious solution. Rather than starting with a pain point, the exercise asked: given the ability to move enormous volumes of air and water through engineered vertical structures, what world-scale challenges might we solve? That thought experiment crystallized into the idea of mega-scale evaporative cooling towers that do far more than reject heat.

Introduction

I had no idea of what this was but I like mega structures and wanted to get it off my mind with no constraints, I iteratively created Mega Evaporator Artefacts using AI and a page of my fragmented thoughts.

The challenge is to create an AI agent to find a problem for this solution. On the first try I created Analysis without the use of an AI agent but it asks the question what is possible if I use a proper framework and subject matter experts? I created the outline Software Requirement Specification for the AI Agent here : AI Agent SRS

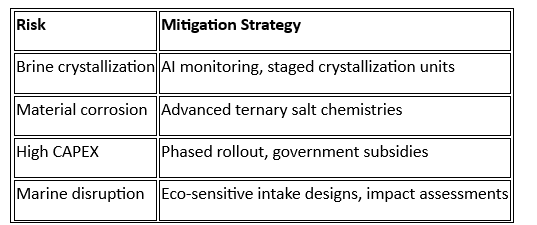

Mega-Scale Evaporative Cooling Towers

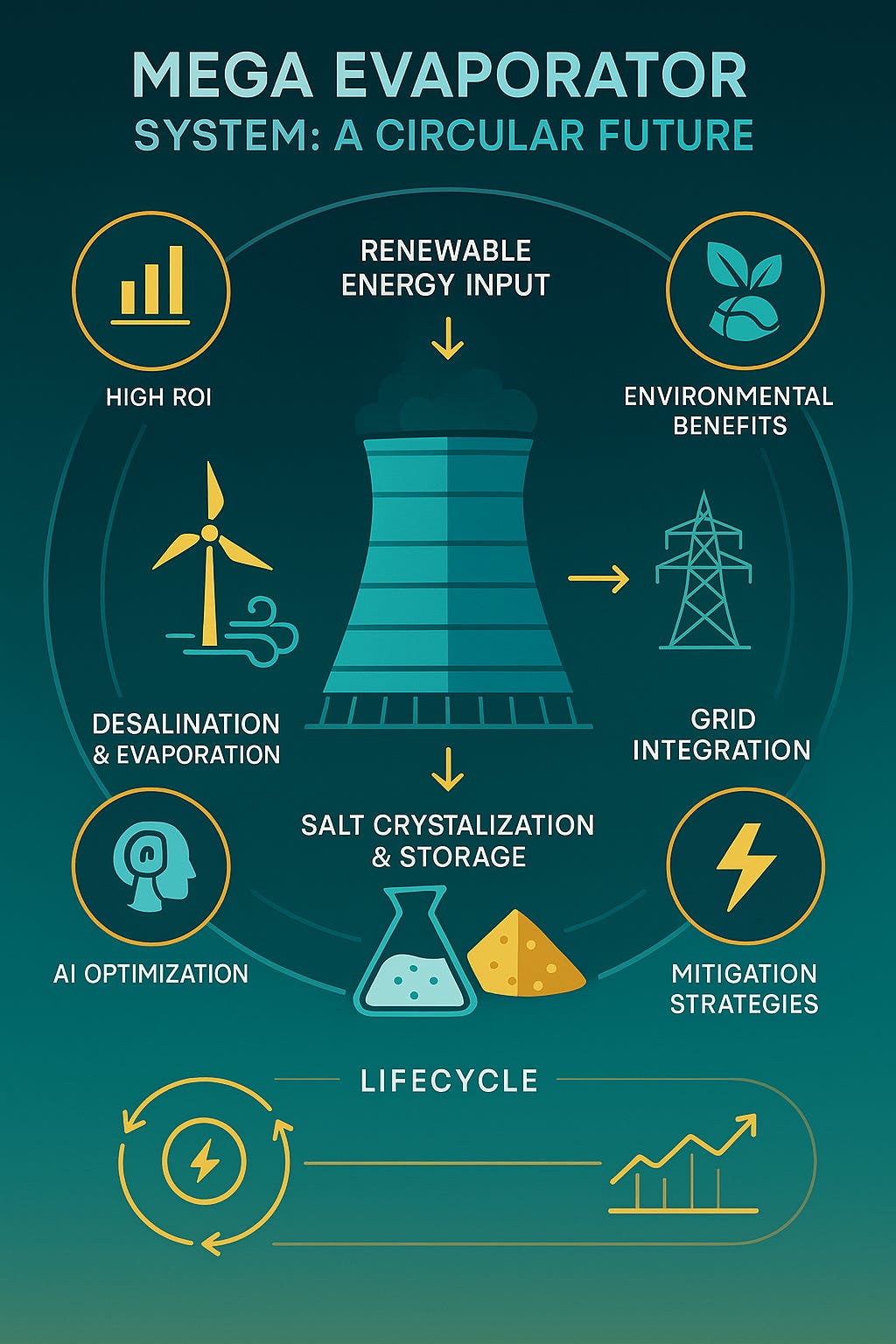

Mega-Scale Evaporative Cooling Towers represent a novel, integrated infrastructure concept designed to tackle multiple global challenges simultaneously primarily water scarcity, renewable energy storage, and resource circularity. Here is a synthesis of their definition and technological significance based on the research:

Mega-Scale Evaporative Cooling Towers are large infrastructure systems that:

- Use evaporative cooling to assist solar and wind-powered desalination of seawater.

- Produce freshwater for industrial/agricultural use.

- Generate salt as a byproduct, which is processed for use in molten salt thermal energy storage.

- Serve as thermal storage systems integrated with the grid to enhance renewable energy deployment.

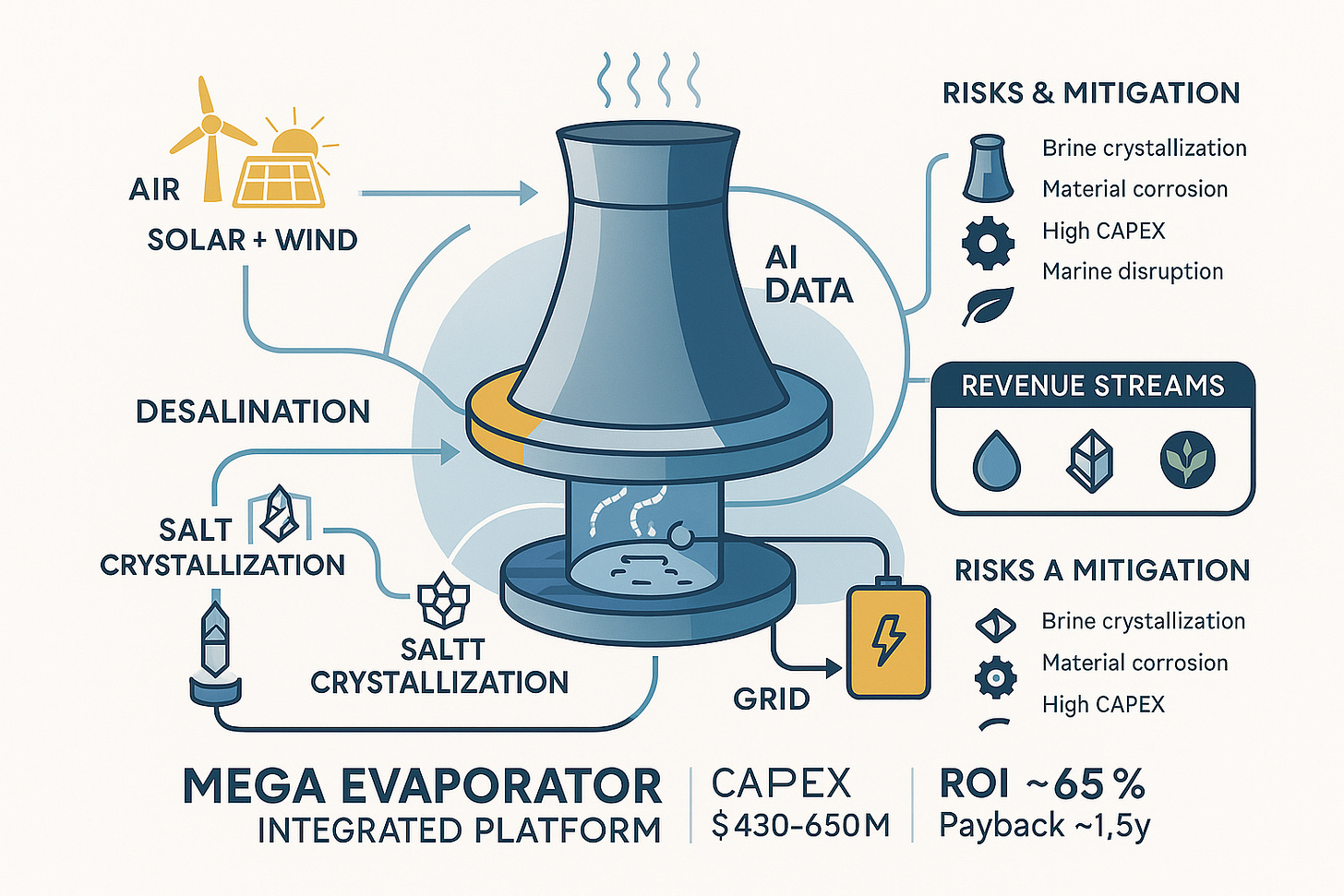

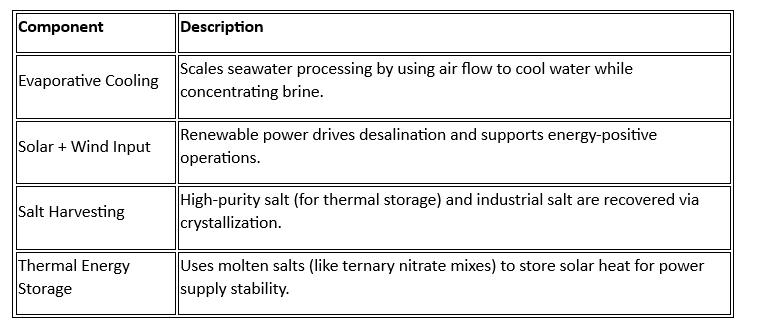

They integrate four core technologies:

- Evaporative Cooling Towers – mature technology from industrial cooling.

- Solar-Thermal Desalination – emerging but promising for zero-emissions water production.

- Zero Liquid Discharge (ZLD) – prevents brine waste, increasing environmental sustainability.

- Molten Salt Energy Storage – long-duration heat storage used in concentrated solar power (CSP) plants.

Technical Highlights

Innovations & Integration Challenges

- Bio-mimetic 3D evaporators for high-salinity water processing.

- Hybrid cooling modes: Mechanical draft during low wind periods, natural draft otherwise.

- AI-driven operations: For balancing water production, energy use, and salt crystallization.

- Modular thermal cascading for staged temperature usage.

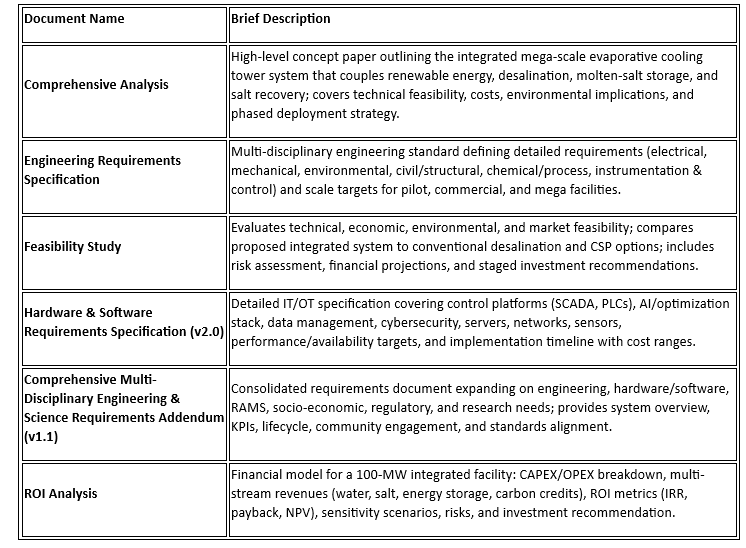

Financial and ROI Metrics

- CAPEX for 100 MW plant: ~$430–650 million

- ROI: ~64.9% (Payback in ~1.5 years)

- Key revenue streams: Water sales, high-purity salt, grid storage, carbon credits.

Environmental Benefits

- Freshwater generation with minimal brine waste.

- Carbon offset via displacement of fossil-based cooling and energy systems.

- Marine ecosystem risk managed through phased intakes and zero-liquid discharge.

Risks and Mitigation

Summary

At full vision, these towers link multiple industrial and sustainability value chains: renewable-powered desalination to produce freshwater; progressive brine concentration and crystallization to recover saleable salts; and molten-salt thermal energy storage that can stabilize grids increasingly dominated by variable solar and wind. By co-locating and thermally cascading these processes, the platform aims to reduce waste streams (including zero-liquid discharge), lower lifecycle emissions, and convert a liability (brine) into an asset (thermal salts and industrial-grade commodities).

Technically, the system draws on well-understood elements (industrial evaporative cooling, CSP-grade salt storage, modular desalination) and layers in advanced controls: hybrid natural/mechanical draft operation, AI optimization to balance water output, salt purity, and energy flows, and a robust OT/IT architecture spanning SCADA, PLCs, cybersecurity, and predictive maintenance analytics. Scaling paths outline pilot, commercial, and mega-facility tiers across mechanical, electrical, civil, chemical/process, and instrumentation disciplines.

Preliminary economics are attention-getting: an indicative 100 MW-class integrated facility shows a capital range on the order of hundreds of millions of dollars yet models attractive multiproduct revenue (water, high-purity salt for thermal storage, grid services, carbon credits) and headline financials including ~65% ROI and payback near 1.5 years under favorable scenarios. Sensitivities, staged investment strategies, and risk flags (materials corrosion, brine handling, environmental permitting) are integral to the case.

This article frames the concept for decision-makers and researchers: What would it take to move from speculative mega-structure to validated infrastructure class? What problems is this solution actually best at solving? Read on.

Conclusion (Where the Idea Goes From Here)

Mega-scale evaporative cooling towers point toward a new category of integrated water-energy-material platforms: infrastructure that converts thermal gradients and saline feeds into multiple revenue streams while advancing decarbonization and resource circularity. The synthesis of desalination, zero-liquid discharge, salt valorization, and long-duration thermal storage could stretch scarce freshwater supplies, firm renewable grids, and reduce waste discharged to sensitive marine environments when thoughtfully sited and managed.

The path forward is not trivial. Multi-system integration across mechanical, chemical, electrical, digital control, and environmental interfaces introduces compounded technical risk. Brine crystallization control, corrosion in high-salinity/high-temperature regimes, high up-front CAPEX, and ecological intake/outfall design all demand tiered demonstration and rigorous standards-driven engineering.

Pragmatically, staged development beginning with modular pilots that validate core process coupling, followed by scaled commercial plants with bankable performance data, can de-risk deployment and improve capital efficiency. Coupling the build-out to diversified revenue (water offtake contracts, salt supply agreements, grid ancillary services) strengthens the investment case and supports attractive IRR and payback profiles observed in early modelling.

Finally, the very way this concept emerged matters: using AI-assisted ideation to surface cross-domain linkages may help infrastructure planners identify unconventional combinations of proven technologies that, together, address multiple global challenges at once. The Mega Evaporator began as a question about what is possible; its next chapter depends on disciplined collaboration to prove what is practical.