Preamble

You are handed a brief (see section below called brief) five minutes before a design meeting, that reads, “Make the Mac Mini portable.” After the shock here is a fast, focused way to use AI:

- Clarify the mission. Ask for the top three use cases, target weight, and preferred display sizes.

- Extract dimensions. Request the exact envelope of the Mac Mini and common portable monitors to lock down footprint.

- Generate form factors. Prompt AI for two or three layout sketches—clamshell, slide-out, or detachable lid, to compare ergonomics.

- Select materials. Query pros and cons of polycarbonate, aluminium, and carbon fiber for weight, cost, and thermal performance.

- Map modular features. Ask for quick-swap bays, universal display rails, and cable-management ideas that keep the desk tidy.

- Draft a spec sheet. Get an instant table of key dimensions, I/O locations, cooling paths, and an estimated bill of materials.

- Outline a storyboard. Request three user scenarios—coffee shop, client demo, and hotel desk, to test practicality.

This rapid sequence gives you a clear concept, a defensible spec, and talking points for stakeholders within minutes.

Fun With AP prompts

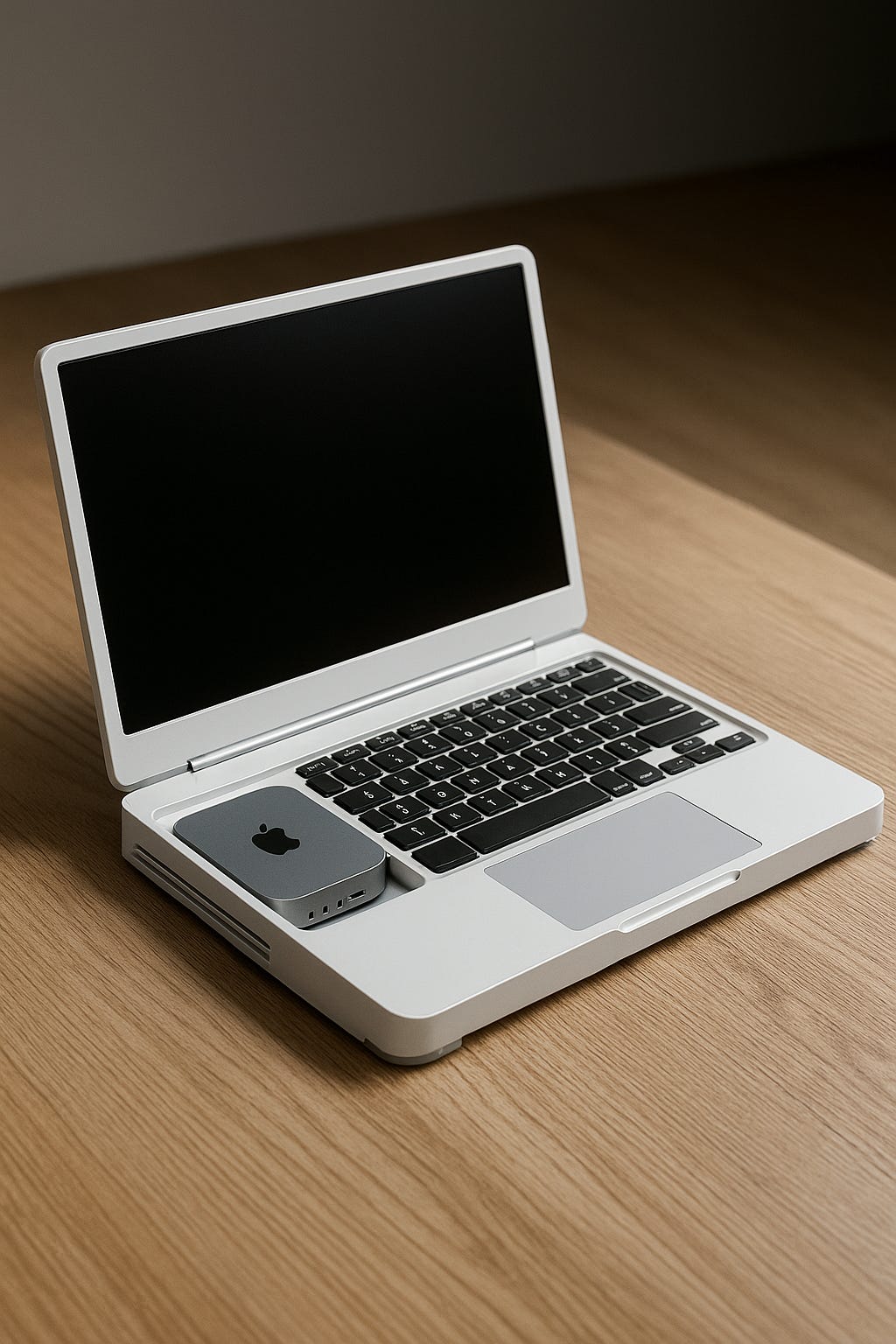

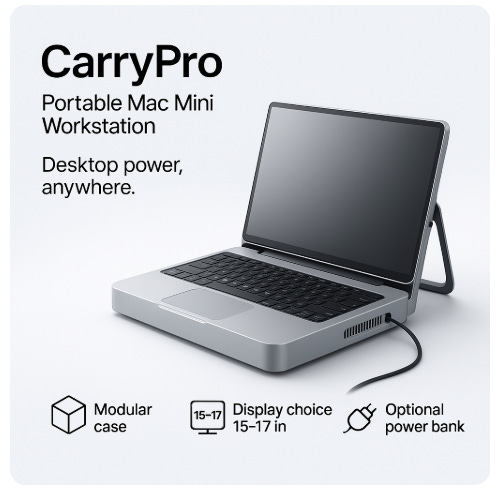

As a product designer, conceptualize a photorealistic case that transforms the Mac Mini into a portable desktop workstation (use attached brief). The design should embody a lightweight, minimalist, and futuristic aesthetic, integrating a functionality that enables chose of display or interface attachment. Prioritize modularity, clean lines, and intuitive portability, usability: suitable for remote work or creative environments. Functionality: portability with some customisation and modularity.

Outputs:

The meeting: Thanks for joining today. These visuals were generated using AI to rapidly explore early-stage concepts based on the brief. They’re not final designs, but rather a way to spark discussion and align on direction. What you’re seeing here represents design thinking—ideas around form, function, and spatial relationships.

These renders help us visualize possibilities and identify what resonates with you. From here, we’ll refine based on your feedback, integrate technical constraints, and move toward a more resolved proposal. So think of these as a starting point, not a finished product

Option A

Option A: Screen size and functionality

Here is a photorealistic concept showing the same minimalist docking-bay chassis paired with two user-swappable displays:

- Left — 15-inch panel clipped into the lid rails

- Right — 17-inch panel using the very same hinge & rail geometry

Both screens mount on a sliding-clip track hidden behind the bezel. The clips adjust outward by 12 mm on each side, so any slim USB-C or HDMI monitor from 15 in to 17 in locks in place without tools. There is the option to creat a single screen captue mechanism allowing max 17-inch but user can choose 15 -inch the mechanism will frame the screen. Everything else aluminium shell, keyboard-and-trackpad tray, side-vent cooling, and Mac mini dock remains unchanged, so you can upgrade or downsize the display whenever your workflow demands.

Option B:

Concept Overview

Your portable Mac Mini workstation centers on one purpose: desktop-grade power anywhere. A single precision-machined case carries the computer, display, input, and cables as one compact kit. The result is quick to deploy, light in the bag, and tidy on any desk or café table.

Key Interactions

- Quick-release lid doubles as a standalone display stand, ideal when you already have a desktop keyboard.

- Keyboard/trackpad tray locks magnetically; slides back under the Mac Mini for transport.

- Handle folds flat; doubles as a kickstand for better screen height.

Manufacturing Snapshot

- Injection-molded PC main parts with living-hinge cable door.

- CNC aluminium hinge barrels for durability.

- Assembly time under 9 minutes; material cost ≈ £14.35, factory gate ≈ £25.95; retail target under £70

Brief

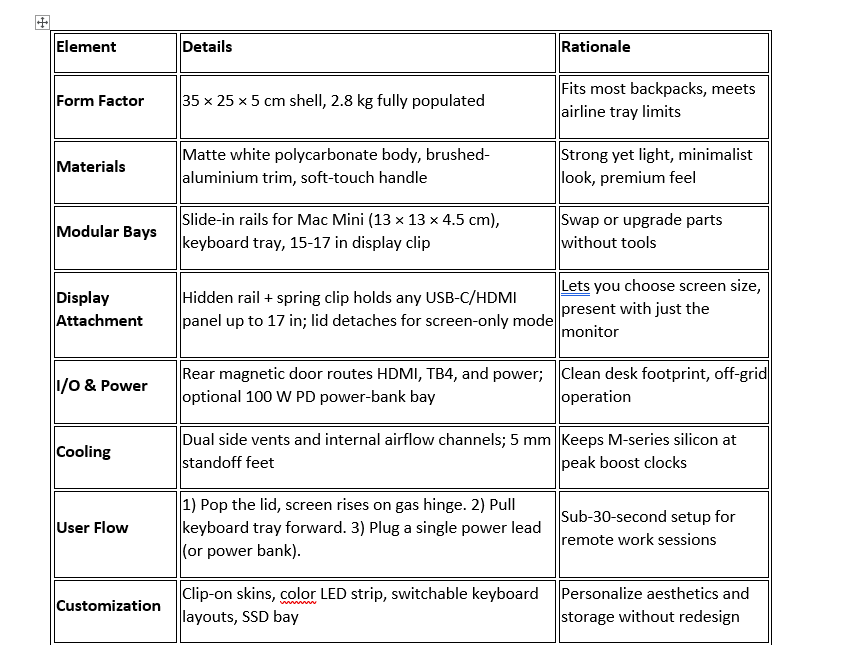

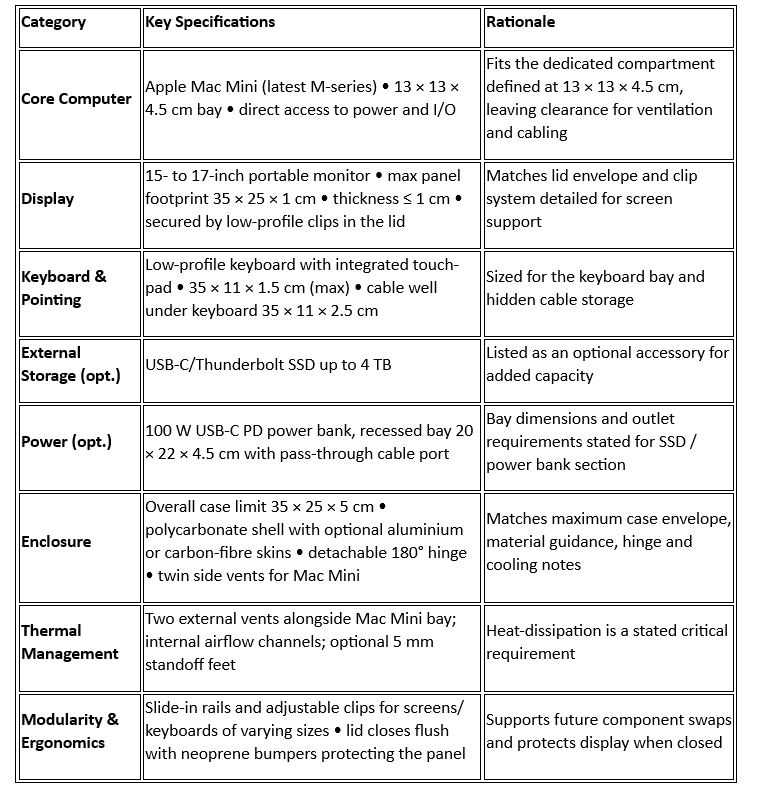

Portable Mac Mini Desktop — Hardware & Software Specification

Create a portable case for Mac mini to convert to a portable desk top for our clients who want to reduce the cost of ownership of Apple products for a new employees who hot desk, this is the specification:

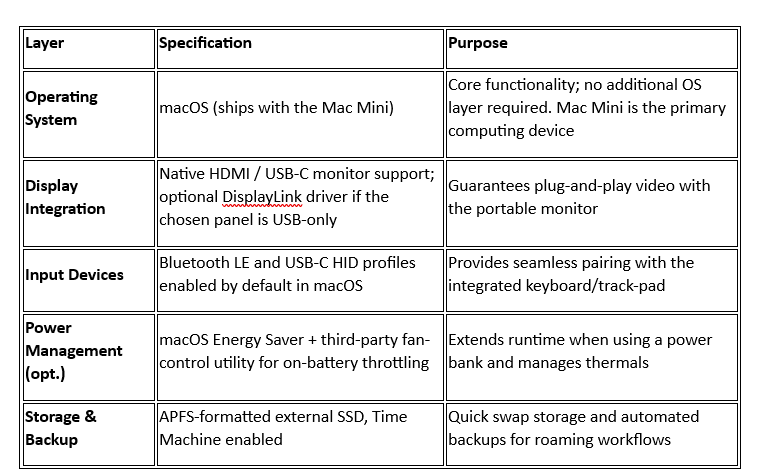

Software Stack

Storage & Backup

APFS-formatted external SSD, Time Machine enabled

Quick swap storage and automated backups for roaming workflows

Assembly Notes

- Cable routing: All ports exit at the rear through two grommeted openings, keeping desk footprint clean.

- Serviceability: Mac Mini and power bank sit under individual hinged covers secured with thumb screws.

- Target weight: < 2.8 kg fully populated (monitor 1.6 kg + Mac Mini 1.2 kg + case 0.4 kg).

- Bill-of-materials ceiling: £50 casing cost to meet the sub-£800 complete system goal .

Appendices

Post client meeting

Assuming that you get the go ahead but the client decided that they want your concept “as is” with a few tweeks to arrive at below yikes! You might need production estimation department to produce the following:

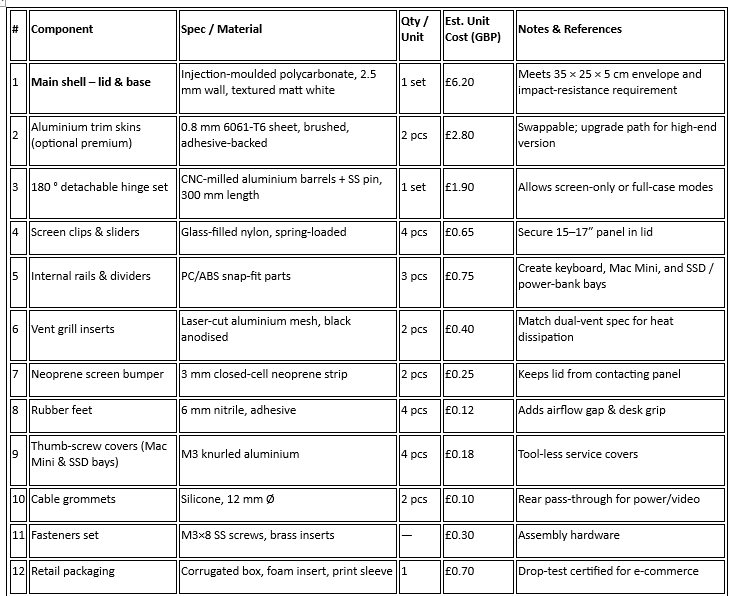

Bill of Materials (BOM) — Mac Mini Portable Desktop Case

This specification gives you the physical tolerances, material choices, and the minimal software stack needed to turn a stock Mac Mini into a truly portable desktop.

Subtotal (materials): £14.35

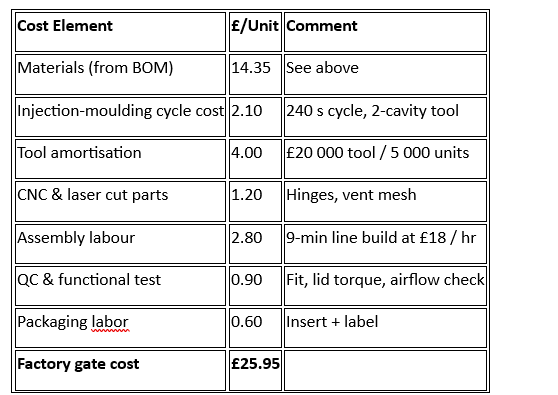

Production-Cost Analysis (per unit, 5 000-unit first run)

Margin Targets

- FOB price to brand (20 % factory margin) → £31.20

- Wholesale to retail (+35 %) → £42.10

- Suggested retail price (+60 %) → £67.40

This keeps the carry-case well under the £50 target for a base model (drop the aluminium skins to reach £45 SRP) and still supports healthy margins, matching the £50-or-less aspiration in the business case .

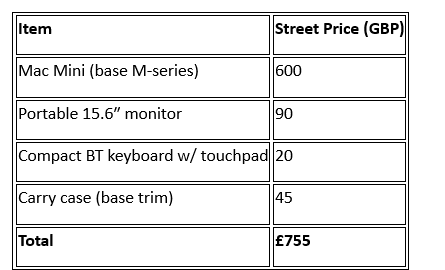

System-Level Cost Check (home user bundle)

Optional add-ons: 1 TB USB-C SSD (£40) and 100 W PD power bank (~£60) keep the configuration under the aspirational £800 ceiling .

Cost-Reduction Levers

- Material shift: Swap aluminium hinge for glass-filled nylon to save ~£1.20 per unit.

- Tool optimisation: Volume above 10 k drops amortisation to ~£1.50 per unit.

- Assembly integration: Ultrasonic-weld dividers into base to remove eight screws and ~£0.25 labour.

These measures provide a clear path to a retail price under £50 without sacrificing durability or heat performance.