Preamble:

How One Shoe Sparked an Entire Design Journey It started with a memory and a picture. A now-discontinued shoe: Merrell Male Ell Spirit Lace Leather Upper in Grey (I think what the model was called) see below:

For me it was more than just footwear. For many, it represented freedom, functionality, and form. Its absence on shelves left a void, prompting a simple but powerful question: Could I recreate something inspired by that legacy, without copying it outright (I did not want to infringe copyright or IP), and could AI help me, do it ?. What began as curiosity evolved into a full-fledged design and development exploration, leveraging artificial intelligence, digital prototyping, and considerations of modern low-volume manufacturing techniques. This post shares that journey, lessons learned, and a practical process that others can replicate to bring their own product dreams to life.

Lessons Learned from Using AI to Reimagine a Legacy Product

- AI is a co-pilot, not the creator

While AI can assist with ideation, mood boards, materials sourcing, and generating design variants, human judgment is still essential for refining the vision and ensuring cohesion. - You do not need to be an expert to start

With the right prompts and tools, it is possible to develop a concept, a materials list, and even a production-ready tech pack even without prior experience in footwear design. - Design systems scale ideas

Using a consistent visual and thematic style sheet allowed exploration across a wide range of variants (sports, brogues, cyberpunk editions) while maintaining a recognizable identity. - 3D visualization accelerates understanding

Generating conceptual sketches and renders before any physical prototyping helped identify what worked visually, structurally, and ergonomically. - Low-volume manufacturing is no longer out of reach

It is now feasible to go from idea to a short-run production of 100–300 pairs using modular tooling, flexible suppliers, and well-documented tech packs.

Some outcomes

Based on Prompts these were some outcomes: Initial concept was then rendered as a casual shoe, boots, a variant and the extension of the design language into a sports shoe design. The outcomes or iterations and variations : Regular, variants, sport and special editions is found here Style . The documentation containing considerations and information for creating the shoe is found here Shoe Production

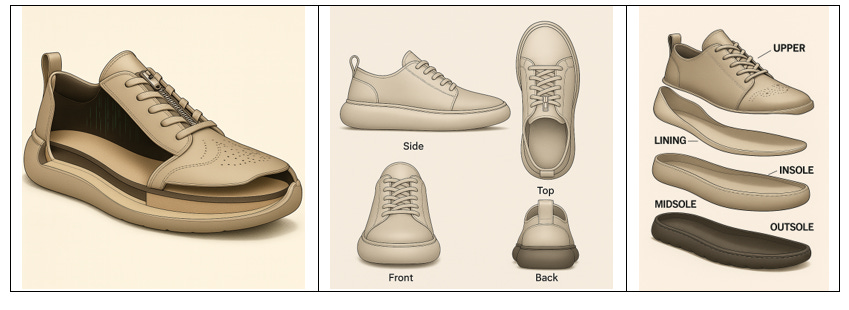

Initial Concept

Visualisation: As a casual shoe, boot, a variant and the extension of the design language to sports shoe design

Views: Cross section, Angles, Exploded

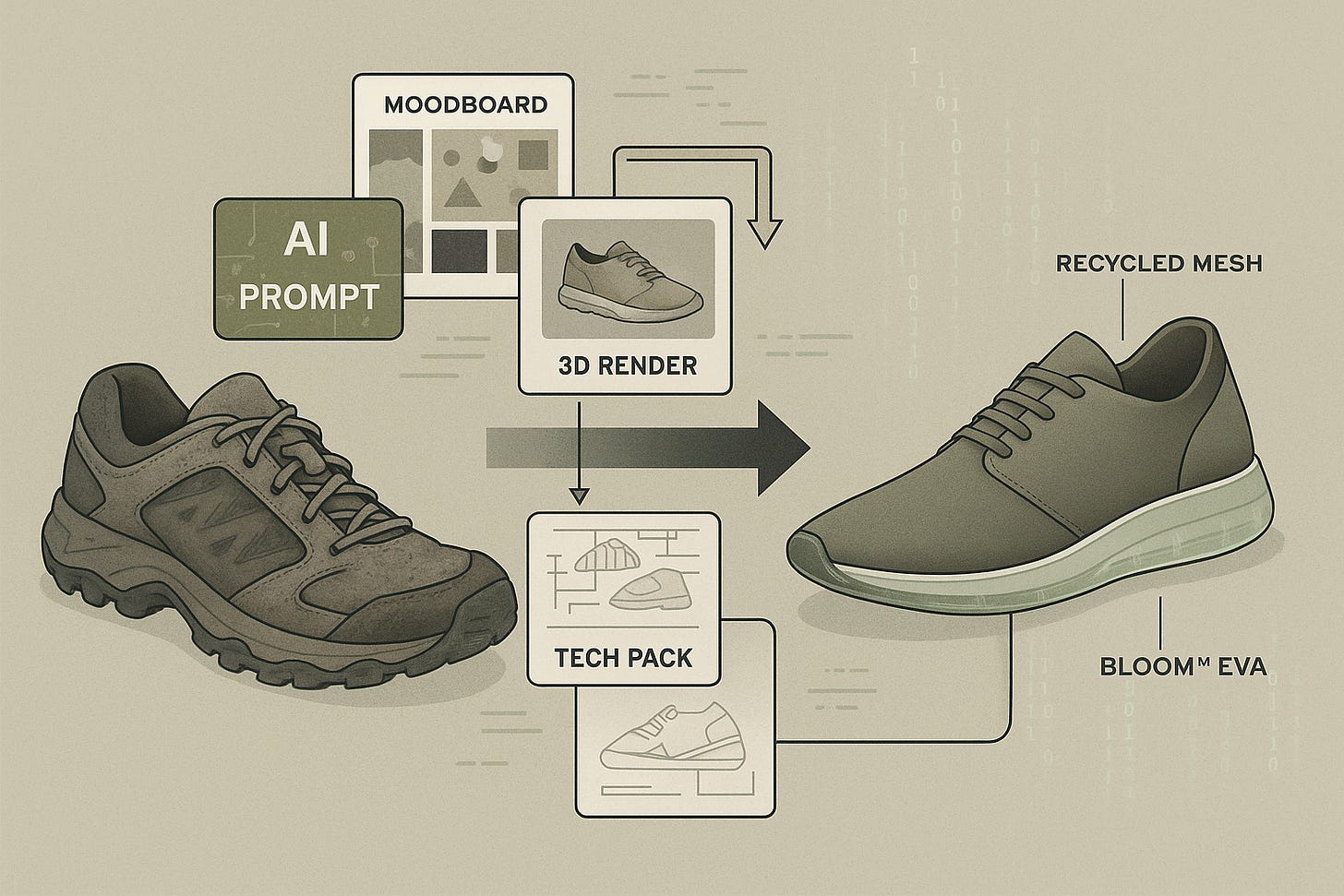

The Process: From Idea to Short-Run Production in the Age of AI

1. Capture the Spark

Use an emotional or aesthetic memory as your design origin. In this case, it was a discontinued trail shoe. Identify what you loved form, feel, function and use it as your conceptual north star.

2. Use AI to Expand Your Vision

Leverage AI for:

- Design prompts to generate variants (e.g. slip-ons, ankle boots, cyberpunk editions)

- Mood boards and style sheets that define the design language

- Material recommendations aligned with your aesthetic and sustainability goals

3. Translate Ideas into a Tech Pack

Build a structured design blueprint:

- Orthographic sketches or picture or references

- Bill of materials (e.g. recycled mesh, BLOOM™ EVA)

- Colourways and style variants

- Labelling, sizing, and construction notes

- Packaging and branding options

Tip: This stage is where AI tools like ChatGPT (for documentation or in this case visuals and rendering ), Midjourney (for visuals) and Fusion 360 or CLO3D (for 3D modelling) become invaluable.

4. Prototype with Purpose

Move from digital to physical:

- Local prototype with what is available old shoes, material, 3D prints

- Look for feedback from specialist or SME and prospective users

- Optional (this was a design exercise) Identify 2–3 suppliers or low MOQ factories (in Portugal, China, or Vietnam) see appendices

- Optional (this was a design exercise) Order an initial prototype and iterate 2–3 times based on fit, feel, and feedback see appendices

Tool: Use sourcing platforms like Maker’s Row, Kompozit Studio, or MFG.com.

5. Ideation, or Learn : Launch?

Once satisfied, do not produce get advice from the professionals, designers subject matter expert, people in the industry who have done similar before (remember to protect your IP): the concept and investigative work and market analysis etc reduces the amount of chargeable work and focuses what needs to be done e.g. due diligence. Talk to prospective customers .Some people will create a small run (100–300 pairs),to test market response (don’t), or pre-sell using platforms like Kickstarter, your newsletter, or Instagram and the success rate is usually quite low. In this case I have no intention it was an design exercise .

Conclusion: Designing in the Age of AI Is not a Shortcut, It is a Shift

This journey proved that designing a small-batch product inspired by a legacy shoe is not a fantasy, it is now a practical, accessible path. AI does not replace expertise, but it collapses the gap between inspiration and execution. From minimalist everyday sneakers to cyberpunk Matrix editions, the combination of digital creativity and short-run manufacturing lets you test bold ideas without betting the house. Whether you are reviving a memory, designing a new product, or building a brand, this is a powerful way to prototype your vision into reality. The surprise was the Positioning; proposed cost, proposed price, choice of quality and variance that can be introduced. The amount of research and analysis remaining : Market and competitor analysis, business plan, brand identity, Market testing , sales and marketing strategy etc. Production: location, specifications, my lack of subject matter knowledge, The number of parts, supply chain, and other complexities in the creation of a shoe.

Appendices

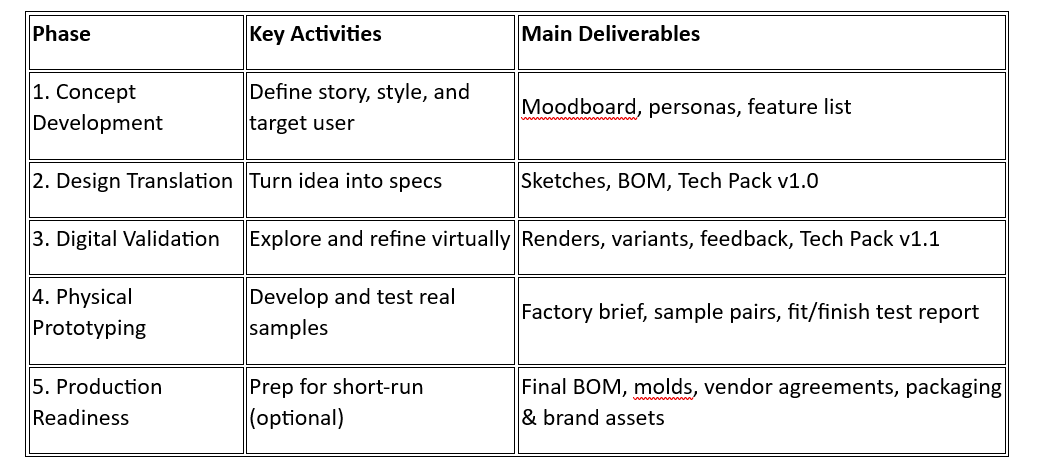

Methodology: From Concept to Prototype for Small-Batch Footwear Production

Outline Structured design methodology for taking a small-batch shoe product from conception to prototype, drawing from industrial design best practices, footwear development standards, and this and brief. Designed for creative entrepreneurs, designers, and makers using AI, sustainable methods, and modular design workflows.(this is an outline)

Phase 1: Concept Development

Objective: Define the vision, user, and aesthetic direction.

🛠 Deliverables:

- Design brief / concept prompt

- User personas & use cases

- Moodboard & visual inspiration

- Initial feature list (fit, function, aesthetics)

Tools & References:

- AI prompt generators (ChatGPT, Midjourney)

- Style & trend forecasting platforms

- [Your] minimalist urban-travel aesthetic brief

Phase 2: Design Translation & Specification

Objective: Turn ideas into tangible documentation.

🛠 Deliverables:

- Technical sketches (orthographic, 3D, exploded views)

- Material & component selection list

- Bill of Materials (BOM) with estimated quantities

- Initial Tech Pack v1.0

Tools & References:

- Fusion 360, Rhino, or CLO3D (for CAD/3D design)

- AI-assisted sketching & visualization

- BOM formats based on industry templates

Phase 3: Digital Prototyping & Validation

Objective: Validate design choices before sampling.

🛠 Deliverables:

- 3D renders or simulations

- Style variants (e.g. slip-on, boot, sports, Matrix editions)

- Feedback session with experts or target users

- Updated Tech Pack v1.1 with visual annotations

Tools & References:

- Blender / CLO3D / Gravity Sketch

- Variant exploration briefs

- Expert design reviews or community critique sessions

Phase 4: Physical Prototyping & Factory Communication

Objective: Convert design into physical sample for wear-testing.

🛠 Deliverables:

- Final Tech Pack v2.0

- Factory-ready sample request (RFQ + specs)

- Prototype(s) — 1 to 3 rounds of iterations

- Fit, function, and finish feedback report

Tools & References:

- Sourcing platforms: Maker’s Row, MFG.com, Alibaba

- Low MOQ factories (China, Vietnam, Portugal)

- Sample review checklist based on ASTM/DIN standards

Phase 5: Production Readiness (Optional)

Objective: Prepare documentation for limited production or pilot batch.

🛠 Deliverables:

- Costed BOM

- Final pattern files or molds

- Supplier contacts and terms

- Sustainability compliance docs (if applicable)

Tools & References:

- ISO/GRS/OEKO-TEX certifications

- Final supply chain map

- Packaging & branding design kit

📋 Summary Table

🔄 Feedback Loops

- Between Phase 2 and 3, run a concept validation round with mockups.

- Between Phase 4 and 5, gather wear-test feedback and iterate if needed.

📚 Knowledge Sources

- Footwear Design by Aki Choklat

- ISO/ASTM footwear testing standards

- Stanford d.school Product Development Toolkit

- GRS/OEKO-TEX/Bluesign material sustainability guides