Preamble

This post explores how diaspora communities can serve as vital stewards of endangered skills, cultural identity, and business continuity offering a proactive alternative to the silent erosion of products and services caused by aging populations, demographic collapse, and shrinking pools of skilled practitioners. Here is an alternative view that centres the role of Japanese, Taiwanese, Korean, and similar diasporas in preserving and relocating endangered capabilities, tied back to the earlier pieces on salvage, transfer, and replication. It is part 2 of The Last Masters Part 1 : Salvaging Cultural Industrial Legacy in Aging Nations . Part 3 looks at The human, cultural preservation and the role of new technology

Why the diaspora matters

Diaspora communities already translate culture, manage trust across borders, and move capital and talent. In a decade of shrinking workforces at home, they can act as the living conduit for knowledge, brand identity, and customer relationships while production footprints shift. This complements your salvage and replication approach, where knowledge capture, digital twins, portable tooling, and staged ramps are the backbone.

Advantages

- Cultural translation and trust

Diaspora operators understand home-country standards and host-country realities. They can run bilingual SOPs, uphold aesthetic targets, and keep tacit cues alive during training and audits. Pair them with your capture and AR operator assist to make tacit skills teachable. - Distributed customer access

Diaspora brands can reopen demand in export markets while a line relocates. Use small certified drops to keep price integrity while you validate quality in a new site. - Lower friction in setup

Diaspora founders often navigate banking, customs, and local permits faster. This reduces downtime when moving vintage equipment and setting up predictive maintenance, spares, and safety retrofits. - Identity continuity

Co-branded marks such as “trained in X tradition, produced in Y under master oversight” feel credible when a diaspora principal stands behind them. Link that to provenance and batch certification.

Disadvantages and risks

- Authenticity drift

Diaspora firms can tilt toward host-market tastes. You need guardrails. Lock sensory and process targets into the spec, not just averages. Publish quality windows and certify operators. - IP leakage and copycat risk

Diaspora networks can spread methods quickly, which helps scale but raises leakage risk. Keep crown-jewel steps in a controlled module. Separate training rights, production rights, and brand rights. Audit routinely. - Elite capture

A small circle may control licenses and tooling, which can exclude origin-country SMEs. Avoid single-gatekeeper models. Use a shared Salvage SPV with transparent access terms and outcome-based fees. - Reputational tension at home

Shifting production can be framed as abandoning local heritage. Use a dual-site model for a period, with limited home-country runs and master-led audits to signal stewardship, not exit.

Culture and history patterns you can use

- Heritage stewardship resonates. Diaspora leaders who frame themselves as caretakers, not owners, gain legitimacy. Pair this with master trainers documented on video and in digital work instructions.

- Precision cultures travel through rituals. Daily line-start checks, sample boards, and defect libraries carry technique as much as machines. Encode these rituals into your pilot playbook.

PESTLE factors to weigh

Political

- Bilateral ties and export controls. Map dual-use checks and origin IP licenses before asset moves. Prefer zones with clear customs paths and temporary admission when training.

- Migration optics at home. Public messaging should stress preservation and future repatriation of capability, not offshoring for cost alone.

Economic

- Premium price retention. Use provenance, audits, and published QC metrics to defend price while you scale outside the origin country.

- Working capital timing. Stage Batch 1 to 3 ramps and tie payments to first-pass yield and on-time delivery, not hours billed.

Social

- Apprenticeship renewal. Fast-track diaspora youth as interpreter-trainers. They shorten cultural distance and can become future master trainers.

- Community legitimacy. Form brand councils that include origin-country masters, diaspora operators, and local trainees to approve changes in materials or finishes.

Technological

- Knowledge capture and AR assist convert tacit moves into teachable steps. Digital twins stress-test climate and input changes before relocation. Inline vision and SPC match legacy signatures, not only averages.

Legal

- Tiered licensing and clear scope. Split brand, method, and training rights. Require audits and revoke on breach. Keep sensitive steps in a controlled module or at a hub.

Environmental

- Vintage machines can be energy-intensive. Use zone power SLAs and targeted retrofits, for example drives and insulation on kilns, to keep heritage output while hitting emissions goals.

Practical operating models

- Diaspora Training Anchor

- Two masters from origin, one diaspora interpreter-trainer, and a host-country cohort.

- Run 12 to 18 months. Certify operators and publish batch data. Then scale with remote oversight.

- Split-process model

- Keep crown-jewel steps at an origin hub. Perform preparatory and finishing steps in the host country. Use sealed modules and QC gates at handoff.

- Brand guild with shared services

- A Salvage SPV owns tooling, licenses, and insurance. SMEs rent time and services. Payments link to yield and warranty performance.

Governance and safeguards

- Provenance by default. QR on every unit. Machine IDs and operator certs linked in a public verifier.

- Change control. Any SOP change triggers a paired test batch and review against the master spec before release.

- Cultural board. Veto rights on brand-critical elements such as glaze palette, weave density, or sound profile. Publish reasons for accepted changes.

Metrics that prove diaspora advantage

- Capability. Number of certified operators produced per master per quarter.

- Quality. Cp and Cpk on the three most sensitive dimensions. Inline defect rate versus legacy baseline.

- Brand. Price premium retention and repeat purchase rate for limited drops that state training lineage.

- Knowledge. SOP comprehension scores and audit pass rate without rework.

Failure modes to watch

- Over-automation that deletes the signature of the craft. Automate measurement and handling first. Keep human judgment where it defines value.

- One-off hero projects with no routinized audits. Bake audits and refresh training into contracts.

- Silent spec drift. Guard with inline sensing and document control. Block conflicting edits.

Endangered capabilities, viable moves

This section ties your candidate industries to concrete locations, roles, cohort sizes, and diaspora pools you can activate. It is written so you can paste it straight into the thread.

What to move, and why

Target lines where tacit skill is high, machines are relocatable, and quality can be verified.

- Precision metalwork and toolmaking. Cutting tools, dies, moulds, gauges, small-lot fixtures. Long apprenticeships, tacit finishing steps, strong portability via CAD, CAM, and digital twins.

- Fine ceramics and kiln crafts. Tableware, tiles, glazes, refractories. Recipes and firing curves at risk; QC via colour and surface metrics.

- Textiles and specialty apparel. Selvedge denim, heritage workwear, narrow-loom fabrics, technical knit. Retiring loom operators; brand value tied to technique that can be audited.

- Musical instruments and acoustic goods. Strings, percussion, reeds, transducers. Sensory specs are lineage-based; provenance protects price.

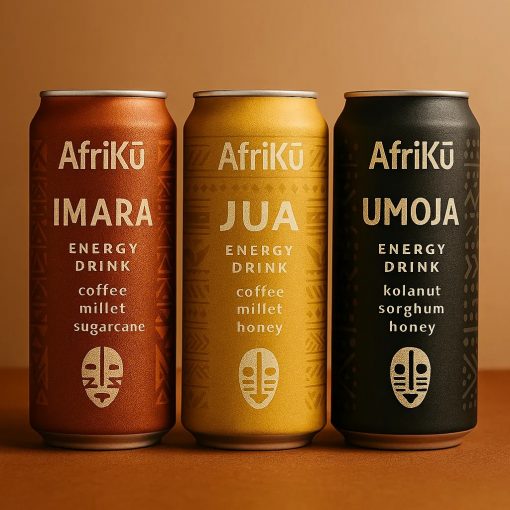

- Specialty food and fermentation. Vinegars, miso, soy sauces, cured fish and meats, traditional confectionery. Identity sits in handling rituals and microbes; diaspora demand can anchor new sites.

- Optical and measurement devices. Microscopes, lenses, metrology subassemblies, dial gauges. Small skilled teams; fit for split-process models that keep crown-jewel steps at origin.

- Restoration and MRO. Analog electronics repair, machine tool rebuilds, classic auto restoration. Expertise concentrated in late-career technicians; AR and twins speed training.

- Printing and finishing. Intaglio, letterpress, artisanal packaging, specialty coatings. Movable presses; inline vision and SPC guard quality.

- Woodcraft and joinery. Precision joinery, shoji, instrument bodies, boatbuilding parts. Tooling travels, technique is tacit; capture on video with bilingual SOPs.

- Small-batch electronics and mechatronics. Actuators, harnesses, control panels, test jigs. Senior techs are exiting; diaspora founders reduce banking and compliance friction.

- Stone, glass, and enamel. Architectural finishing, stained glass, enamel signage. Underused heavy kit; clear retrofit paths for controls and safety.

- Niche agriculture and processing. Tea, seaweed, specialty mushrooms, heritage grains. Rural depopulation; strong diaspora markets for certified origin methods.

Where to place first pilots

Origin hubs with high succession risk

Japan, South Korea, Taiwan, and clusters in Italy, Germany, Portugal, Spain, and Central Europe. Use split-process or master-audited models to protect identity.

Likely host locations and roles

Southeast Asia for operator scale and bilingual talent, South Asia for metrology and machining depth, Mexico and Turkey for nearshore access. Use hosts for training cells, tooling replication, phased ramps, and trainer ladders under master and diaspora oversight.

Who runs it

Build four operator archetypes into every site. Interpreter-trainers, diaspora principals, quality custodians, and cultural stewards who sit on brand councils and approve finish or recipe changes.

How big to start

Design a one-year pilot per capability. 12 to 20 operators, 1 diaspora interpreter-trainer, 2 rotating masters. One production cell plus a duplicate of the most failure-prone station for drills, and a calibrated QC bench. Run three staged batches to hit 85 percent then 92 percent then 95 percent plus first-pass yield before scale. Certify 10 to 15 operators, promote 2 to 3 cell leads, track 1 to 2 toward trainer status.

Portfolio scale in year one. Stand up 2 to 3 origin hubs that hold crown-jewel steps and run audits. Launch 4 to 6 host training cells across two countries, each tied to one product family. Audit quarterly and publish provenance. Prove demand with two limited drops per family into diaspora markets.

Diaspora pools to tap

Use available expatriate and ancestry communities to seed trainers, QC, and early buyers.

- Japan. About 1.29 million Japanese nationals abroad, with large groups in the United States, Australia, China, Canada, and Thailand; broader diaspora about 4.0 million. This supports trainer recruitment and early market drops.

- Korea. About 7.08 million in the global Korean diaspora, concentrated in the United States, China, Japan, Canada, and Uzbekistan. Strong base for interpreter-trainers and QC custodians.

- Taiwan. About 2.095 million R.O.C. nationals overseas, with 1.297 million in the Americas. Broader diaspora near 1.94 million. Good fit for pilot buyers and bilingual technical roles.

Sizing rules of thumb. In a given city, assume 0.05 to 0.2 percent of the local diaspora pool can qualify as interpreter-trainers or QC custodians within 6 to 12 months. For early drops during ramp, plan for 0.5 to 2 percent of the local diaspora as reachable buyers. For every 50 trained operators, staff one traveling diaspora QC custodian.

Quick matching guide

- Precision metalwork. Start in Vietnam or India; keep tool finishing at a Japan hub for six months.

- Ceramics. Place cells in Thailand or Portugal-like zones with energy SLAs; hold glaze formulation at origin.

- Textiles. Start in Vietnam or Turkey; move pattern grading last after operator certification.

- Musical instruments. Body work in Indonesia or Mexico; keep voicing and final tuning at origin for a year.

- Fermentation foods. Primary fermentation at an origin hub; finishing and packaging at host sites after sensory alignment.

A short action plan for a diaspora-led pilot

- Pick one product family at real risk. Scan tooling, capture golden parts, and record master sessions. Draft bilingual SOPs.

- Stand up a training cell in a zone with reliable power. Ship a starter kit of inputs to calibrate early batches.

- Run three staged batches. Publish QC and provenance. Do a limited diaspora-market drop to test price and story.

- Decide scale, hold, or rollback based on yield, warranty returns in 90 days, and audit scores.