Preamble

This is a contribution to Developing the world: Achieving a future Type I Civilization Part 1. And a continuation to Achieving a future Type I Civilization Part 2: Precursors to developing a Type 1 Civilisation

This is post explores one of many ideas on technical precursors for accelerating world development. Occasionally, I come across someone on YouTube who has built a car or device somewhere, and it is impressive for what it is—limited resources, back-to-basics innovation, or starting from first principles (usually in the third world)? It is fascinating to see such ingenuity in action. But this got me thinking: as a civilization, have we reached the point where we can compile a comprehensive production database of how to build anything—from basic to advanced—just like the resources available in the 3D printing community. Would this stifle ingenuity? I do not think so as its purpose is a curated product consisting of foundational knowledge, framework, methodology and database. It is a foundational cornerstone to the building of an advanced civilisation.

Introducing the World Production Framework and Database

Framework

A framework is a foundational structure that supports and guides the development of complex systems or processes. It provides a theoretical underpinning, incorporating methodologies, processes, and tools, backed by a comprehensive body of knowledge and references. While non-prescriptive in nature, a framework empowers users to create a tailored pathway, transforming initial requirements into tangible solutions. By offering flexibility within a structured approach, frameworks enable efficient and systematic problem-solving across various disciplines.

Global Production Database Framework

This framework aims to provide a holistic view of the production process, enabling users to efficiently source parts, understand manufacturing technologies, apply scientific principles, follow assembly processes, and utilize detailed schematics to achieve varying levels of product sophistication. It serves as a valuable resource for engineers, manufacturers, and anyone involved in the creation of products. A Global Production Database Framework is a comprehensive, structured system designed to manage and disseminate detailed information related to the production of various machinery, or products ranging from basic car engines to sophisticated industrial equipment. This framework encompasses several key components:

- Inputs and Resources:

- Material Sourcing: Information on raw materials, suppliers, and procurement processes.

- Components: Detailed specifications and sources for parts and sub-assemblies.

- Manufacturing Technology:

- Processes: Descriptions of manufacturing techniques, including traditional and advanced methods.

- Equipment: Information on machinery and tools required for production.

- Science and Principles:

- Engineering Principles: Fundamental theories and principles underlying the design and operation of machinery.

- Material Science: Properties and applications of materials used in manufacturing.

- Assembly Processes:

- Step-by-Step Guides: Detailed instructions for assembling components into finished products.

- Quality Control: Procedures for ensuring product quality and consistency.

- Schematics and Blueprints:

- Design Documents: Technical drawings and schematics for various machinery.

- CAD Models: Computer-aided design files for precise manufacturing and assembly.

- User Guidance:

- Tutorials and Manuals: Educational resources to guide users through each stage of production.

- Troubleshooting: Solutions for common issues encountered during manufacturing.

Database

Imagine a global production database that covers everything from building a basic car engine to producing sophisticated machinery. This database would provide detailed information on inputs, manufacturing technology, science and principles, material science, assembly processes, and schematics. It would guide users through each step, from sourcing parts to achieving different levels of sophistication.

Such a database would not be limited to automotive projects. It could include instructions for creating out-of-patent drugs, consumer goods, industrial products, and more. It would provide essential information on material science, sourcing components, manufacturing processes, current development status, government regulations, and more. Any patented material or process would be referenced, with guidance on how to obtain necessary licenses or access to intellectual property.

The potential users of this database are diverse: hobbyist craftsmen, researchers, universities, small and large-scale manufacturers. The goal is to empower people and countries to manufacture products at a fundamental level, using proven methods and technologies. The database would outline requirements for subject matter expertise, materials, cost breakdowns, worksheets, input sources, and references to essential equipment.

Creating such a database requires a structured approach, ensuring comprehensive coverage of all aspects necessary for manufacturing various products. Emphasis on collaboration, validation, and continuous improvement would ensure that this resource remains valuable for all users, fostering innovation and knowledge sharing on a global scale.

As usual the first question is that does this exist and the answer is “yes” in different formats (see appendices for likely frameworks and databases that might exist) but with different objectives\ use cases, stakeholders, accessibility, and curation.

I would be remiss to mention that as Business consultant there is a Business Architecture Guild who have created a business architecture framework with reference models, and a body of knowledge on how to use it and this could be referenced for the creation and modelling business for different industries and is adaptable for startup to mature industries. It is called the BIZBOK guide this at a higher level of abstraction than specific product\ services. I am sure there are various frameworks and databases in various industries, they might not be global and comprehensive.

Outline for a Global Production Database

1. Introduction

- Purpose: To create a comprehensive, open-access database for manufacturing all known products, enabling users from various sectors to replicate, innovate, and enhance production processes.

- Target Users: Hobbyist craftsmen, researchers, universities, small and large-scale manufacturers, and governments.

2. Database Structure:

- User Interface – Web-based portal – Mobile app accessibility

- Data Organization – Categories by product type – Search and filter functions

- Data Integrity and Security – Regular updates – Peer-reviewed entries – Data encryption and user authentication

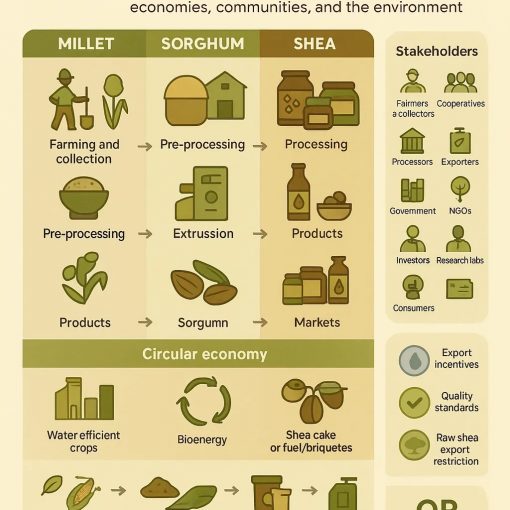

3. Product Categories: Consumer Goods- Industrial Products – Medical and Pharmaceutical – Automotive – Technology and Electronics – Agricultural Tools and Equipment

4. Database Content Requirements

- Product Overview – Description – Applications and uses

- Subject Matter Knowledge and Expertise – Detailed explanation of the necessary expertise – educational resources and links to training materials

- Materials – List of raw materials – Sources and suppliers – Material properties and alternatives

- Production Process – Detailed step-by-step instructions – Flowcharts and diagrams – Videos and tutorials

- Manufacturing Technology – Equipment required – Manufacturing techniques (e.g., 3D printing, machining, assembly) – Innovations and emerging technologies

- Science and Principles – Underlying scientific principles – Technical specifications

- Cost Breakdown – Detailed cost analysis \ tools – Budgeting and financial planning tools

- Input Sources – Suppliers and procurement options – Geographic availability

- References and Patents – Citations of relevant patents – Instructions for obtaining licenses or permissions

- Regulations and Compliance- Industry standards – Government regulations – Certification requirements

5. Database Functionality

- Search and Filter – Keyword search – Filter by product category, complexity, material, and cost User Contributions – User submission forms – Peer review and validation system

- Collaboration Tools – Forums and discussion boards – Project management and collaboration features

6. Validation and Curation

- Information Reliability – Peer-review system – Expert verification

- Curation Process – Regular updates and audits – Community feedback integration

7. Case Studies and Examples

- Example Projects – Step-by-step case studies (e.g., building a basic car from scratch)

- Highlighted projects and user success stories

8. Implementation Roadmap

- Phase 1: Planning and Design – Requirements gathering – Database design and architecture

- Phase 2: Development – Backend and frontend development – Initial data population

- Phase 3: Launch and Testing – Beta testing with selected users – Public launch

- Phase 4: Expansion and Scaling – Adding new products and categories – Enhancing features based on user feedback

9. Potential Challenges and Solutions

- Data Overload – Effective categorization and filtering

- Intellectual Property Issues – Clear guidelines on patent use – Collaboration with legal experts

- Data Validation – Robust peer-review and expert validation

- User Engagement – Incentives for contributions – Community building activities

10. Future Directions

- Integration with AI and Machine Learning – Personalized recommendations- Predictive analytics for production optimization

- Global Collaboration Network – Partnerships with educational institutions and industries – Global manufacturing alliances

- Impact on Global Manufacturing – Empowering local manufacturers – Promoting innovation and knowledge sharing

- Call to Action – Encouraging participation from various stakeholders – Building a sustainable and collaborative knowledge platform

Advantages and Disadvantages of using the World Production Database

The World Production Database has the potential to revolutionize manufacturing globally by providing equitable access to comprehensive production knowledge. However, its implementation must be carefully managed to address infrastructure, legal, quality, economic, and security challenges. By doing so, countries can maximize the advantages while minimizing the disadvantages, ultimately fostering a more innovative, efficient, and equitable global manufacturing landscape.

Advantages

1. Economic Growth and Diversification

- Local Manufacturing Empowerment: By providing access to detailed manufacturing knowledge, local manufacturers can produce a wider range of products, leading to economic growth and job creation.

- Value Chain Participation: Countries can participate more fully in global value chains, moving from raw material suppliers to producers of finished goods.

2. Educational Enhancement

- Practical Learning: Universities and colleges can use the database as a teaching tool, providing students with real-world applications of their theoretical knowledge.

- Research and Development: Researchers can access a wealth of information, fostering innovation and the development of new technologies and processes.

3. Innovation and Technological Advancement

- Collaboration and Knowledge Sharing: The database encourages collaboration between different sectors, leading to the sharing of best practices and innovations.

- Access to Cutting-Edge Information: Users can stay updated on the latest manufacturing technologies and techniques, helping them to remain competitive.

4. Resource Efficiency

- Material Optimization: Detailed information on materials and processes can help manufacturers optimize their use of resources, reducing waste and lowering costs.

- Sustainability: Access to sustainable production methods can promote environmentally friendly practices.

5. Global Equality

- Reducing Knowledge Gaps: The database can help level the playing field, providing less-developed countries with access to the same information as their more developed counterparts.

- Boosting Local Industries: Local industries can develop and expand, reducing dependence on imports and increasing self-sufficiency.

Disadvantages

1. Implementation Challenges

- Infrastructure Requirements: Effective use of the database requires reliable internet access, modern manufacturing facilities, and skilled labour, which may be lacking in some regions.

- Initial Investment: Setting up the necessary infrastructure and training personnel can be costly.

2. Intellectual Property and Legal Issues

- Patent Restrictions: Some technologies and processes may be patented, limiting the ability of users to freely utilize all the information available.

- Regulatory Compliance: Different countries have varying regulations, which can complicate the implementation of standardized manufacturing processes.

3. Quality Control and Information Reliability

- Data Validation: Ensuring the accuracy and reliability of the information in the database is crucial but challenging. Incorrect or outdated information can lead to production issues.

- Quality Assurance: Maintaining consistent product quality across different regions with varying levels of expertise and resources can be difficult.

4. Economic Disruption

- Local Market Impact: The ability to produce a wide range of products locally can disrupt existing markets and supply chains, affecting businesses that rely on imports or exports.

- Competition: Increased local production can lead to intense competition, potentially harming smaller businesses that cannot compete with larger, more efficient manufacturers.

5. Security Concerns

- Cybersecurity Risks: A centralized database with valuable manufacturing information can be a target for cyberattacks, risking the theft of sensitive data.

- Misuse of Information: There is a risk that the information could be used to produce harmful or illegal products.

Building the World Production Database: Requirements: People, Process, and Technology

Building The World Production Database is a multifaceted project requiring a well-coordinated effort involving skilled professionals, robust processes, and advanced technologies. By addressing the requirements across people, process, and technology, the database can be developed to serve as a valuable resource for global manufacturing, fostering innovation, and enhancing production capabilities worldwide.

People Requirements

1. Project Management

- Project Managers: To oversee the development, implementation, and maintenance of the database.

- Stakeholder Managers: To engage and manage relationships with key stakeholders, including universities, manufacturers, and government agencies.

2. Technical Team

- Software Developers: For database development, web interface design, and mobile app development.

- Database Administrators: To manage and maintain the database infrastructure.

- Data Scientists: To ensure data integrity, validation, and the implementation of AI and machine learning for predictive analytics.

- Cybersecurity Experts: To protect the database from cyber threats and ensure data security.

3. Content Experts

- Subject Matter Experts (SMEs): In various fields such as automotive, pharmaceuticals, consumer goods, and industrial products to provide accurate and detailed information.

- Technical Writers: To document processes, create user guides, and ensure the information is accessible and understandable.

- Quality Assurance Specialists: To verify the accuracy and reliability of the content.

4. Collaboration and Support

- Community Managers: To facilitate user engagement, manage forums, and handle user feedback.

- Training and Support Staff: To provide training materials and assist users in navigating and utilizing the database.

Process Requirements

1. Planning and Design

- Requirement Analysis: Gathering and analysing requirements from potential users and stakeholders.

- System Design: Designing the database architecture, user interface, and overall system structure.

2. Development

- Database Development: Creating the backend database infrastructure.

- Interface Development: Developing user-friendly web and mobile interfaces.

- Content Creation: Collecting and curating comprehensive manufacturing information.

3. Validation and Testing

- Data Validation: Ensuring the accuracy and reliability of the information.

- System Testing: Conducting thorough testing to identify and fix bugs and issues.

4. Deployment and Maintenance

- Implementation Plan: Rolling out the database in phases, starting with a beta version for selected users.

- Maintenance Plan: Regular updates, data audits, and system improvements.

5. Collaboration and Feedback

- User Engagement: Encouraging contributions and feedback from users.

- Peer Review Process: Implementing a peer review system to validate user-submitted content.

6. Legal and Compliance

- Regulatory Compliance: Ensuring the database complies with local and international regulations.

- Intellectual Property Management: Managing patents, licenses, and intellectual property issues.

Technology Requirements

1. Infrastructure

- Cloud Services: For scalable storage and computing resources.

- Servers: Reliable servers for hosting the database and web services.

- Networking: High-speed internet connections and secure network infrastructure.

2. Database Technology

- Database Management System (DBMS): A robust DBMS such as MySQL, PostgreSQL, or Oracle.

- Data Warehousing: For storing and managing large volumes of data.

- Backup Systems: Regular backups to prevent data loss.

3. Software and Tools

- Development Frameworks: Such as Django, Ruby on Rails, or Node.js for web development.

- APIs: For integration with other systems and data sources.

- Collaboration Tools: For project management and team collaboration (e.g., Jira, Trello, Slack).

4. Security

- Encryption: End-to-end encryption for data in transit and at rest.

- Firewalls and Intrusion Detection Systems: To protect against unauthorized access and cyber threats.

- Access Control: Role-based access control to ensure only authorized users can modify or access sensitive data.

5. User Interface

- Web Interface: Responsive and user-friendly web design.

- Mobile Application: Mobile apps for iOS and Android for accessibility on the go.

- Search and Filter Capabilities: Advanced search functions to help users find relevant information quickly.

6. Data Analytics

- AI and Machine Learning: For predictive analytics and personalized recommendations.

- Reporting Tools: For generating insights and reports on database usage and trends.

Conclusion

Incorporating academic and research content into The World Production Database can significantly enhance its value, providing users with access to cutting-edge knowledge and fostering innovation. This integration can be achieved through a phased approach, starting with foundational integration in the initial development phase, followed by the creation of a dedicated research database as a supporting product, and further enhanced in future development stages with real-time updates and community contributions. By doing so, the database can serve as a comprehensive resource that bridges the gap between academic research and practical manufacturing knowledge. Part 4 will examine the pathway for implementation the world production framework \ Database and the Analysis: SWOT and PESTLE.

Appendices

Frameworks and databases

This is an outline list of similar frameworks and databases that likely exist for different products, industries, and services. (needs verification) Remember, while these types of frameworks and databases likely exist in various forms, their accessibility, comprehensiveness, and global nature may vary. You would need to research each industry specifically to find the most relevant and up-to-date resources.

Several existing databases and platforms provide resources, information, and collaboration opportunities for manufacturing, agriculture, and sustainable development. Here are a few examples:

1. World Bank’s Agriculture Data

- Description: Provides comprehensive data on agricultural production, trade, and policies.

- Stakeholders: Governments, researchers, policy makers, development organizations.

2. FAO’s (Food and Agriculture Organization) FAOSTAT

- Description: Offers data on agricultural production, trade, food security, and more.

- Stakeholders: Farmers, researchers, policy makers, development organizations.

3. UN Comtrade Database

- Description: Provides international trade statistics and data on trade flows between countries.

- Stakeholders: Governments, researchers, economists, trade organizations.

4. MIT’s Observatory of Economic Complexity

- Description: Visualizes global trade data, showing what countries export and import.

- Stakeholders: Economists, researchers, businesses, policy makers.

5. Google Scholar

- Description: Aggregates research papers and theses from various fields, including manufacturing and technology.

- Stakeholders: Researchers, students, academics, businesses.

6. Open-Source Ecology

- Description: A collaborative platform providing blueprints and guides for building industrial machines and technologies.

- Stakeholders: Hobbyists, small manufacturers, educators, researchers.

7. FabLabs

- Description: A global network of local labs offering digital fabrication tools and resources.

- Stakeholders: Makers, small manufacturers, educators, students, researchers.

8. Data management and processing

These frameworks and databases are designed to handle various aspects of data management and processing. These are tailored for different use cases and industries.

- Hadoop – Description: An open-source framework for storing and processing large amounts of data. It is designed for batch processing, stream processing, and real-time analytics, making it ideal for handling big data workloads.

- Apache Spark – Description: A unified analytics engine for large-scale data processing. It provides high-level APIs in Java, Scala, Python, and R, and an optimized engine that supports general execution graphs.

- MongoDB – Description: A NoSQL database known for its flexibility and scalability. It stores data in JSON-like documents, making it easy to work with complex data structures.

- PostgreSQL – Description: An advanced, open-source relational database system known for its robustness, extensibility, and standards compliance. It supports both SQL and JSON querying.

- Redis – Description: An in-memory data structure store used as a database, cache, and message broker. It supports various data structures such as strings, hashes, lists, sets, and more.

- Presto – Description: An open-source distributed SQL query engine for running interactive analytic queries against data sources of all sizes. It is designed for fast analytics on large datasets.

Conceptual but not verified Frameworks and databases

These are some framework and database that I think should exists but the route to finding them will involve trade associations , disparate information and academic research

1. Global Automotive Manufacturing Database: Description: Comprehensive database covering all aspects of automotive manufacturing, from basic engines to advanced vehicle systems.

2. Pharmaceutical Production Framework Description: A framework detailing the processes, regulations, and technologies involved in pharmaceutical manufacturing.

3. Consumer Electronics Production Database: Description: Database covering the manufacturing processes for various consumer electronics, from basic components to complex devices.

4. Industrial Machinery Production Framework: Description: A framework outlining the production of industrial machinery, including design, assembly, and quality control processes.

5. Aerospace Manufacturing Database: Description: Comprehensive database on aerospace manufacturing, covering materials, processes, and regulations for aircraft and spacecraft production.

6. Food Processing Industry Framework: Description: A framework detailing the processes, equipment, and regulations involved in industrial food production.

7. Textile Manufacturing Database: Description: Database covering all aspects of textile production, from raw material processing to finished product manufacturing.

8. Renewable Energy Systems Production Framework: Description: A framework outlining the manufacturing processes for various renewable energy technologies, such as solar panels and wind turbines.

9. Medical Device Manufacturing Database: Description: Comprehensive database on medical device production, including regulatory requirements, materials, and manufacturing processes.

10. Construction Industry Production Framework: Description: A framework detailing the processes, materials, and technologies used in various types of construction projects.