Preamble

This is an outline for an end-to-end method for turning nature’s strategies into solutions , hence a work in progress and inspiration. The framework anchors on three levels of design, form, process, and system, and a six-step loop that starts with function, moves through biological search and principle abstraction, then into prototyping and evaluation with Life’s Principles, before iterating. This gives teams a repeatable path from brief to build. The document also maps inspiration to application across sectors, from passive cooling in buildings to nacre inspired composites and swarm algorithms for logistics. The result is a practical catalogue that helps a project team translate biology into materials, computing, energy, mobility, and service design choices. BMWs study of fish provides design inspiration: BMW Study

This is an outline framework see appendices for considerations to improve this framework . This is related to previous post Idea Trigger No. 13 Biomimicry: Charting the Future of Nature-Inspired Innovation

Core Philosophy

Biomimicry is learning from 3.8 billion years of nature’s R&D to solve human challenges through forms, processes, and systems that have already been tested and refined by evolution.

Three Levels of Biomimetic Design

- FORM – Copying structures to gain function (shapes, textures, patterns)

- PROCESS – Emulating how nature builds, senses, repairs, optimizes

- SYSTEM – Designing networks and ecosystems that create circular, zero-waste economies

The 6-Step Design Process

1. DEFINE FUNCTION CLEARLY

Start with what the solution must DO, not what it should LOOK LIKE

Questions to ask:

- What problem are we solving?

- What must this accomplish?

- What are our constraints? (cost, scale, materials, timeline)

- What environmental conditions will it face?

Example: Instead of “design a better adhesive,” ask “how do we attach things in wet environments?”

2. FIND BIOLOGICAL CHAMPIONS

Search broadly across diverse species and ecosystems

Where to look:

- Organisms facing similar challenges

- Extreme environments (deserts, deep ocean, Arctic)

- Evolutionary transitions

- Extinct species with unique adaptations

Resources:

- AskNature.org – searchable database of biological strategies

- Academic journals in biology, ecology, physiology

- Natural history museums and collections

- Field biologists and ecologists

Example functions mapped to nature:

- Adhesion in wet conditions → Geckos, mussels, slugs, barnacles

- Passive cooling → Termites, elephants, camels

- Water collection → Namib beetles, spider webs, cactus

- Strength with minimal material → Spider silk, bone structure, bamboo

- Self-repair → Skin, trees, bone healing

- Energy efficiency → Photosynthesis, bird flight, whale swimming

3. ABSTRACT DESIGN PRINCIPLES

Translate biological strategies into engineering-compatible rules

The translation process:

- Observe the biological strategy in detail

- Identify the key mechanisms (structural, chemical, behavioral)

- Determine which aspects are essential vs. incidental

- Reframe in functional language

- Create design briefs connecting biology to application

Example:

- Biological observation: Lotus leaves repel water and stay clean

- Key mechanism: Hierarchical micro- and nano-structures minimize surface contact; waxy coating increases hydrophobicity

- Design principle: Create multi-scale textured surfaces with low surface energy coatings

- Application: Self-cleaning paints, fabrics, solar panels

4. EMULATE & PROTOTYPE

Build using available materials, fabrication methods, and computational tools

Approaches:

- Start simple – use readily available materials

- Computational modeling before physical fabrication

- 3D/4D printing for complex geometries

- Bio-based materials when possible

- Hybrid approaches combining biomimetic principles with advanced engineering

Manufacturing considerations:

- Nature builds at ambient temperature with water as solvent

- Industry often requires heat, pressure, toxic processes

- Bridge the gap through: additive manufacturing, bio-based polymers, room-temperature synthesis, self-assembling materials

5. EVALUATE WITH LIFE’S PRINCIPLES

Check prototypes against nature’s design criteria

Life’s Principles Checklist:

RESOURCE EFFICIENCY

- ✓ Uses multifunctional design

- ✓ Recycles all materials

- ✓ Fits form to function

- ✓ Uses low-energy processes

ADAPTATION & RESILIENCE

- ✓ Incorporates diversity

- ✓ Maintains integrity through self-renewal

- ✓ Embodies resilience through variation and redundancy

- ✓ Integrates local learning

INTEGRATION WITH SYSTEMS

- ✓ Uses locally available resources

- ✓ Cultivates cooperative relationships

- ✓ Leverages cyclic processes

- ✓ Uses feedback loops

EVOLUTION & OPTIMIZATION

- ✓ Builds from the bottom up

- ✓ Self-organizes

- ✓ Optimizes rather than maximizes

- ✓ Uses chemistry compatible with life

6. ITERATE

Improve based on testing results and new biological insights

- Measure performance against conventional solutions

- Identify failure modes and limiting factors

- Return to biological models for additional strategies

- Refine based on user feedback and real-world conditions

- Test in relevant environmental conditions

Product Design Inspiration by Category

ARCHITECTURE & CONSTRUCTION

Thermal Management:

- Termite mounds → Passive ventilation systems (90% energy reduction)

- Prairie dog burrows → Natural air circulation through pressure differentials

- Polar bear fur → Hollow fiber insulation

Structural Efficiency:

- Tree branching patterns → Load-optimized support structures

- Bone microstructure → Lightweight, high-strength materials

- Coral exoskeletons → Mineralized composites

Water Management:

- Lotus leaves → Self-cleaning surfaces

- Mangrove roots → Selective filtration systems

- Forest ecosystems → Integrated water catchment and storage

MATERIALS SCIENCE

Adhesives:

- Gecko feet → Micro-structured dry adhesives for reusable bonding

- Mussels → Protein-based wet adhesives for medical and marine applications

- Slug mucus → Bio-adhesives for surgical tissue bonding

- Barnacles → Permanent underwater attachment systems

Structural Materials:

- Nacre (abalone shell) → Layered composites with exceptional impact resistance

- Spider silk → High-strength, elastic, self-repairing fibers

- Bone → Hierarchical structures from nano to macro scale

- Wood → Anisotropic, fiber-reinforced composites

Smart Materials:

- Blood clotting cascade → Self-healing polymers

- Plant turgor → Pressure-responsive actuators

- Chameleon skin → Color-changing surfaces

- Pine cone scales → Heat-activated shape change

Circular Materials:

- Mycelium → Biodegradable packaging and building materials grown from agricultural waste

- Bacterial cellulose → Compostable textiles and films

- Chitin → Bioplastics from crustacean shells

ENERGY

Solar:

- Leaf microstructures → 47% efficiency increase through light-capturing geometry

- Photosynthesis → Direct conversion of sunlight to chemical energy

- Butterfly wing structures → Light-trapping nanostructures

Wind & Water:

- Humpback whale tubercles → 32% better lift, delayed stall in turbine blades

- Kelp blades → Flexible structures for variable current conditions

- Amazonian seeds → Low-speed wind capture designs

Storage & Distribution:

- Leaf veins → Resilient microgrids that reroute around faults

- Mycelial networks → Distributed resource allocation systems

- Tree vascular systems → Efficient fluid transport without pumps

Cooling:

- Saharan silver ants → Radiative cooling surfaces

- Elephant ears → Passive heat dissipation

- Termite mounds → Stack effect ventilation

WATER & FILTRATION

Water Collection:

- Namib beetle exoskeleton → Fog harvesting through textured surfaces

- Spider webs → Condensation capture

- Cactus spines → Directional water channeling

- Warka Water Towers → Atmospheric moisture extraction (25-100L daily)

Filtration & Purification:

- Mangrove roots → Selective salt filtration

- Wetland systems → Multi-stage natural purification

- Aquatic plant roots → Microplastic and pollutant removal

- Oyster reefs → Bio-filtration combined with habitat creation

- Baleen whale filters → Large-volume particle separation

TRANSPORTATION & MOBILITY

Aerodynamics:

- Kingfisher beak → Streamlined nose design (30% noise reduction, 15% energy savings)

- Bird feathers → Morphing winglets for adaptive drag reduction

- Boxfish → Low-drag body shapes

Locomotion:

- Canine gait → Balanced, adaptive movement for rough terrain (Boston Dynamics Spot)

- Octopus arms → Soft robotics for flexible manipulation

- Insects → Micro-air vehicles with complex flight dynamics

Efficiency:

- Whale fins → Drag-reducing vehicle mirrors

- Shark skin (riblets) → Friction-reducing surface textures

- Bird formations → Energy-efficient fleet coordination

DIGITAL & COMPUTING

Algorithms:

- Ant colony foraging → Distributed scheduling and routing optimization

- Slime mold pathfinding → Network design and shortest-path solutions

- Bird flocking → Swarm intelligence for autonomous systems

- Mycelial networks → Data routing that adapts around congestion

Architecture:

- Neural networks (brain) → Parallel, event-driven processing

- Immune systems → Distributed security and threat detection

- Coral reefs → Reputation systems rewarding cooperation

Energy Efficiency:

- Neuromorphic computing → Brain-inspired chips using 1000x less power

- Sparse activation patterns → Event-driven computation

- Natural cooling patterns → Data center thermal management

HEALTHCARE & MEDICINE

Surgical Applications:

- Boa constrictor fangs → Backward-facing serrations for clot removal catheters

- Slug mucus → Tissue adhesives for wet surgical environments

- Mussel proteins → Bonding agents for internal wounds

Antimicrobial Surfaces:

- Shark skin riblets → Bacterial attachment prevention

- Cicada wings → Nanostructures that mechanically kill bacteria

- Lotus leaf hierarchy → Self-cleaning medical devices

Drug Delivery:

- Barnacle adhesion → Microscale anchoring for sensors and patches

- Mosquito proboscis → Painless needle designs

- Gecko adhesion → Transdermal delivery systems

AGRICULTURE & FOOD

Regenerative Farming:

- Mycorrhizal networks → Nutrient distribution between plants

- Prairie root systems → Deep-rooted perennial crops (3m roots for erosion prevention, carbon sequestration)

- Coral reef stabilization → Mixed-species bed design preventing soil erosion

- Forest succession → Multi-layer food production systems

Urban Food Systems:

- Forest canopy → Vertical farm light distribution

- Wetland cycling → Aquaponics nutrient loops

- Bee corridors → Integrated pollination pathways in city planning

Pest Management:

- Plant defense chemistry → Natural pesticides

- Predator-prey dynamics → Biological pest control

- Companion planting → Ecosystem-based crop protection

WILDFIRE & ENVIRONMENTAL MONITORING

Detection:

- Serotinous pine cones → Heat-activated wildfire sensors using bio-based organic electronics

- Beetle infrared detection → Forest fire monitoring systems

- Plant stress signals → Early warning biosensors

Service Design Applications

LOGISTICS & SUPPLY CHAIN

- Ant trail reinforcement → Swarm-scheduled delivery optimization

- Leaf vein networks → Redundant distribution systems

- Slime mold efficiency → Route optimization for minimal energy

URBAN PLANNING

- Forest resource flows → Circular urban metabolism with redundancy and feedback

- Watershed systems → Integrated water management (streets, parks, roofs as catchments)

- Mycelial networks → Decentralized infrastructure coordination

ORGANIZATIONAL DESIGN

- Bee colonies → Self-organizing teams with distributed decision-making

- Immune systems → Adaptive organizational resilience

- Ecosystem diversity → Innovation through varied perspectives and redundancy

Context-Specific Innovation Pathways

EMERGING ECONOMIES (Low-Cost, Locally-Adapted)

Priority needs:

- Off-grid water access (fog harvesting, dew collection)

- Passive thermal comfort (termite-inspired ventilation, camel fur textiles)

- Circular micro-manufacturing (mycelium packaging from agricultural waste)

- Low-cost mobility (tendon-like cable systems for strength with minimal material)

Design principles:

- Use locally available materials

- Minimize energy requirements

- Enable local production

- Design for repair and longevity

DEVELOPED ECONOMIES (High-Tech Integration)

Priority opportunities:

- AI-enhanced aerospace (morphing winglets, swarm control)

- Advanced biotech (self-healing materials, antimicrobial surfaces)

- Ecosystem-grade urban design (watersheds as integrated systems)

- Biomimetic computing (distributed algorithms, energy-efficient processing)

Design principles:

- Leverage advanced manufacturing

- Integrate with digital systems

- Optimize through AI and simulation

- Scale through industrial processes

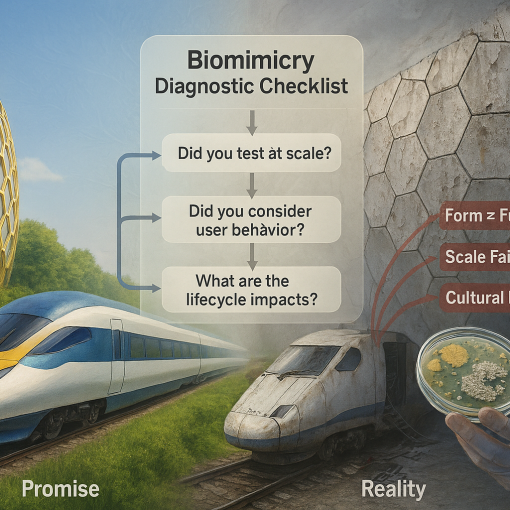

Overcoming Key Challenges

THE TRANSLATION GAP

Challenge: Nature uses ambient temperature, water as solvent, benign chemistry. Industry uses heat, pressure, toxic processes.

Solutions:

- Hybrid approaches combining biomimetic principles with engineering

- 3D/4D printing for complex geometries

- Bio-based polymer development

- Room-temperature synthesis pathways

- Self-assembling materials

INTERDISCIPLINARY COMMUNICATION

Challenge: Biologists speak fitness and adaptation. Engineers speak stresses and tolerances.

Solutions:

- Shared taxonomies and ontologies

- Joint design sprints with co-location

- Prototyping spaces for both biological observation and engineering testing

- Interdisciplinary team training

SYSTEMS COMPLEXITY

Challenge: Ecosystems couple energy, materials, water, and information in ways current tools can’t capture.

Solutions:

- Multiscale modeling and digital twins

- Simulation stacks testing across scales

- Machine-readable biological strategy databases

- AI-assisted pattern recognition

Enabling Technologies & Risk Assessment

The practical application of biomimicry is being dramatically accelerated by advancements in technology. These tools bridge the gap between biological inspiration and human-made implementation, but their use must be evaluated against the core principles of biomimicry.

AI & Machine Learning: The Pattern Recognition Engine

Role in the Framework:

AI acts as a powerful catalyst, primarily in the FIND and ABSTRACT stages. It can rapidly parse vast biological datasets from platforms like AskNature, academic journals, and genomic databases to identify non-obvious biological strategies for a given function.

- Accelerated Discovery: Machine learning algorithms can identify structural and functional patterns across millions of species, suggesting novel biological champions for design challenges (e.g., finding a desert plant’s water-capture strategy to solve an industrial condensation problem).

- Generative Design & Simulation: AI can generate thousands of design variations based on abstracted biological principles (e.g., bone microstructure) and simulate their performance under real-world conditions, far exceeding human iteration speed.

- Optimization of Complex Systems: AI can help optimize biomimetic systems, such as swarm robotics algorithms inspired by ant colonies or mycelial networks, by modeling their emergent behaviors.

Risk Profile:

- Over-Optimization: AI may converge on a single, highly optimized but brittle solution, whereas nature values redundancy and diversity for resilience.

- Data Bias: Models are only as good as their training data. Gaps in biological data can lead to skewed or incomplete solutions.

- Black Box Problem: Complex AI models can obscure the underlying biological principle, divorcing the design from its natural mentor and making it harder to apply Life’s Principles authentically.

3D & 4D Printing: Fabricating Nature’s Complexity

Role in the Framework:

This technology is central to the EMULATE & PROTOTYPE stage, allowing for the physical realization of complex, hierarchical, and organic geometries found in nature that are impossible to create with traditional subtractive manufacturing.

- Complex Geometries: Precisely fabricate micro-structured surfaces (lotus leaf, shark skin), intricate internal lattices (bone, coral), and optimized load paths (tree branching).

- Multi-Material Printing: Create composite structures that mimic the graded properties of natural materials like nacre or beak.

- 4D Printing (Shape-Morphing): Create objects that change form in response to environmental stimuli (e.g., humidity, temperature), emulating biological processes like pine cones opening or plant tendrils coiling.

Risk Profile:

- Material Limitations: Many printers rely on polymers and resins that are not biodegradable or derived from sustainable sources, conflicting with the “Chemistry Compatible with Life” principle.

- Energy Intensity: The printing process can be energy-intensive, especially for high-resolution metal or ceramic parts, potentially negating resource efficiency gains.

- Scalability & Waste: Scaling from prototype to mass production remains a challenge, and support material waste can be significant if not managed in a circular way.

Robotics & Advanced Fabrication (e.g., Castless Forming)

Role in the Framework:

Robotics enables the emulation of nature’s processes—how things are built and move. This applies to the EMULATE and SYSTEM levels.

- Bio-Inspired Robotics: Develop agile robots using locomotion principles from animals (e.g., canine gait for rough terrain, octopus arms for delicate manipulation).

- Additive & Swarm Manufacturing: Use robotic arms for large-scale additive manufacturing or coordinate swarms of smaller robots to construct structures from the bottom up, mimicking termites or bees.

- Castless Forming (e.g., Directed Energy Deposition, Cold Spray): These advanced techniques “grow” metal parts layer-by-layer without molds, mimicking biological growth processes. This eliminates waste from casting molds and allows for creating complex, optimized geometries with minimal material.

Risk Profile:

- High Cost & Complexity: Advanced robotic systems and castless forming technologies require significant capital investment and specialized expertise, creating barriers to entry.

- Embodied Energy: The energy required to process raw materials (e.g., metal powders for deposition) can be high.

- Unintended Consequences: Autonomous bio-inspired robotic systems could have unforeseen impacts if deployed at scale in complex environments (e.g., disruption of ecosystems by monitoring drones).

New Science & Tech Inputs

- Synthetic Biology: Moving beyond emulating to engineering with biology. This involves programming organisms (bacteria, yeast, mycelium) to grow materials, sense environmental changes, or perform computations, directly harnessing nature’s processes.

- Risk: High uncertainty and potential for ecological disruption if genetically modified organisms are released. Raises profound ethical questions.

- Advanced Materials Science: Development of self-healing polymers (inspired by blood clotting), phase-change materials (inspired by animal fat for thermal regulation), and programmable meta-materials (inspired by chameleon skin).

- Risk: Potential for novel pollutants if these advanced materials are not designed for safe circularity or biodegradation from the outset.

Integrated Risk Mitigation Strategy

When applying these technologies within the biomimicry framework, continuously evaluate them against Life’s Principles:

- Use Life-Friendly Chemistry: Prioritize bio-based, biodegradable, or easily recyclable materials in all fabrication processes.

- Be Resource Efficient: Choose manufacturing methods that minimize waste (additive over subtractive) and energy consumption.

- Embrace Diversity & Redundancy: Use AI to generate a portfolio of diverse solutions, not just one “perfect” answer.

- Integrate Cyclic Processes: Design the end-of-life for the product and its manufacturing byproducts from the very beginning.

By treating these powerful technologies as tools in service of nature’s wisdom, rather than replacements for it, we can ensure our innovations are not just clever, but also truly sustainable and resilient.

Essential Resources

Knowledge Platforms

- AskNature.org – Searchable biological strategies database (enhanced 2025 AI chat feature)

- Biomimicry Institute – Life’s Principles framework and methodology

- Biomimicry 3.8 – Professional training and Design Lens tool

Funding & Acceleration

- Ray of Hope Accelerator – Biomimetic venture development

- Biomimicry Global Design Challenge – Annual innovation competition

- Government R&D grants for biomimetic research

- Green bonds for biomimetic infrastructure

Frameworks

- Life’s Principles – Nature’s design criteria for evaluation

- Circular Economy principles (Ellen MacArthur Foundation) – System-level alignment

- Cradle to Cradle – Material health and circularity

Quick-Start Design Prompts

For Product Innovation:

- What does nature do when facing this same challenge?

- How can we achieve this function using less material and energy?

- What would this product look like if it “grew” instead of being manufactured?

- How would this fit into a circular system where waste doesn’t exist?

- What can we learn from organisms in extreme environments?

For Service Innovation:

- How do natural systems distribute resources efficiently?

- What biological networks exhibit resilience and adaptation?

- How does nature handle feedback and self-correction?

- What ecosystem patterns could improve our value network?

- How do living systems optimize without centralized control?

The Biomimicry Mindset

Treat Nature As:

- Mentor (not just resource)

- Library (of proven strategies)

- Model (for sustainable systems)

- Measure (for evaluating designs)

Design Principles:

- Optimize rather than maximize

- Use chemistry compatible with life

- Build from bottom up

- Self-organize

- Use locally available resources

- Cultivate cooperative relationships

- Leverage cyclic processes

Measuring Success

Performance Metrics:

- Energy savings vs. conventional solutions

- Resource efficiency (material use, water, land)

- Durability and lifespan

- Recyclability and biodegradability

- Ecosystem services provided (carbon sequestration, water filtration, habitat)

Life-Friendly Criteria:

- Does it use renewable energy?

- Are all materials recyclable or compostable?

- Does it function in local conditions without external inputs?

- Can it be repaired and maintained locally?

- Does it enhance rather than degrade ecosystems?

The Future: Bio-Digital Fusion

Next Decade Trends:

1. Design from Databases

- AI-accelerated biological strategy search

- Natural language queries returning ranked solutions

- Pattern recognition identifying cross-domain analogies

2. Fabrication That Mimics Growth

- 3D/4D printing creating impossible-with-traditional-methods geometries

- Bio-based polymers replacing petroleum derivatives

- Grown products (cultured leather, mycelium packaging, bacterial cellulose)

3. Ecosystem-Grade Planning

- Cities designed like watersheds

- Infrastructure with diversity, feedback loops, adaptive capacity

- Urban systems mimicking forest resource management

Final Framework Summary

The biomimicry design process is circular, not linear:

DEFINE FUNCTION → FIND CHAMPIONS → ABSTRACT PRINCIPLES → EMULATE → EVALUATE → ITERATE → (return to any step as needed)

Always ask:

- What would nature do?

- How can we do it with less?

- Does this align with Life’s Principles?

- Can this return safely to earth or technical cycles?

Remember: 3.8 billion years of evolution has already solved the problems we face. Our role is to observe, learn, translate, and implement with humility and respect for the mentor that is the natural world.

Conclusion

Biomimicry works when you keep function first, learn from biological champions, translate mechanisms into engineering language, and test against Life’s Principles. Use the catalog to seed options, then prototype with available processes and evaluate system impacts, not only part performance. Treat nature as mentor, model, library, and measure. Keep the loop active, define, find, abstract, emulate, evaluate, iterate, and bring solutions that fit local conditions and return safely to biological or technical cycles.

Appendices

This framework is a living document. As biomimicry evolves and new biological strategies are discovered, continue adding to and refining these principles. Nature’s solutions are infinite our challenge is learning to read them.

Further proposed developments

- Case evidence and benchmarks. Include two to three short case studies per sector with problem, biomimetic principle, result, time to deploy, cost delta, and measured impact such as energy saved or defect rate reduced. A standard one page case template would help teams compare options.

- Metrics pack and worksheets. Add worksheets for Define, Abstract, and Evaluate, including a Life’s Principles scorecard with weighted criteria and a sample KPI set for energy, materials, water, durability, and circularity. The document references these steps and principles, but teams need fillable artifacts to use in workshops.

- Decision trees. Provide quick decision trees that connect common functions, such as attach in wet conditions or reduce drag, to candidate biological strategies, manufacturing routes, and risk flags. The current tables list strategies, a flow that guides choice would speed adoption.

- Prototyping playbook. Add bill of materials examples, preferred bio based polymers, room temperature processes, and a small library of printable unit cells for nacre, bone, or kelp inspired lattices, with notes on print settings and test protocols. The framework points to additive and 4D printing, the how to would close the gap.

- Systems modeling starter kit. Include a simple digital twin scaffold for water, energy, and material flows at neighborhood scale, plus a checklist for feedback loops, redundancy, and local resource use. This extends the system level guidance into a first model build.

- Governance, ethics, and IP. Add guidance on field collection ethics, attribution to biological knowledge sources, open versus proprietary strategy, and a short note on regulatory pathways for medical, building, and food applications.

- Team roles and cadence. Define roles across biology, engineering, design, and business, with a four to six week sprint cadence, meeting agendas, and artifacts due at each gate.

- Adoption roadmap. Provide three rollout paths, an emerging economy track focused on local materials and maintenance, a developed economy track focused on high tech integration, and a blended path for partnerships. Link each to the context pathways already outlined.

- Visual aids. Add a single page poster of the six step loop, a icons set for Life’s Principles, and sector specific maps that show function to strategy to prototype at a glance.

- Further reading and supplier list. Close with a short, curated bibliography, plus a starter directory of labs, printers, materials, and test houses aligned with life friendly chemistry.