Preamble

This blueprint turns idle waterfront assets into working platforms for food, jobs, and cleaner water. We reuse abandoned piers and retired ships, add solar, wind, and wave power, and run seaweed lines, bivalve racks, and restoration modules. Robotics handle inspection and harvest. A microgrid and heat pump dryers cut energy cost. Processing on deck keeps quality high and shortens the cash cycle. We measure yield, water quality, and habitat gains with a clear MRV plan. Read the primer that set the stage here: https://open.substack.com/pub/cabusinessdesignconsultancy/p/ideas-trigger-10-the-blue-green-economy?r=59m4go&utm_campaign=post&utm_medium=web&showWelcomeOnShare=false. This document focuses on site types, hardware kits, energy mixes, data flows, permits, and a 12 month pilot you can start now.

Blue Green Agricultural Economy on Abandoned Piers and Decommissioned Ships

Practical concept, issues, hardware spec, and pilot blueprints

1) Purpose and scope

Reuse abandoned piers and decommissioned ships as near-shore hubs for aquaculture, small-scale fishing recovery, ecosystem restoration, and environmental cleanup. Power operations with solar, wind, and wave. Run robotics and data systems for safe, measurable output. Build an upgrade path from pilot to clustered networks. The tech stack, yields, processing flow, and MRV build on your AquaOS work and seaweed production reports.

2) Asset base and scale signal

- Disused platforms worldwide number roughly 1,500 to 2,000 still standing. These show what is possible when marine structures are repurposed for ecology and industry.

- Abandoned or disused piers are not centrally tracked. A conservative global estimate exceeds 100,000 structures when you include small private and commercial docks.

- Decommissioned or laid-up ships awaiting disposal sit in the low thousands at any point in time, with several hundred naval vessels in the mix.

3) Site archetypes you can deploy

- Urban or industrial pier conversion. Shore power tie-ins, community access, quick logistics, and strong stakeholder visibility.

- Rural or estuary pier. Space for habitat and cleanup pilots near nutrient sources.

- Ship-as-hub. A decommissioned Ro-Ro or small container ship converted to a floating hatchery, processing, energy, and data center, moored to a pier or anchored within a harbor.

- Ship-as-collector. Mobile mother ship that seeds, services, and harvests nearby farms and restoration arrays, then returns to a processing pier.

4) Core functions per site

- Agriculture. Seaweed longlines, bivalve racks, controlled “artificial farm” pods for premium marine crops. Yields for sugar kelp plan at 75 to 200 tonnes wet per hectare per season in temperate waters. Manage moisture and iodine through processing and timing.

- Fishing recovery. Habitat modules, fish aggregation devices, and seasonal no-take zones tied to community rules.

- Restoration. Floating wetlands, reef blocks, eelgrass nurseries, and monitored nutrient removal plots.

- Cleanup. Bio-based sorbent pilots near legacy contamination, turbidity and litter capture around piers, and verified removal logs.

5) Energy microgrid, renewables mix

Targets for a medium pier or ship hub

- Daily demand 3 to 6 MWh across hatchery, pumps, dryers, cold chain, robotics, and IT. Peak 250 to 500 kW. Use a DC backbone with grid-forming inverters, 2 to 4 MWh LFP battery, and optional 100 kW electrolyzer with storage and a 100 kW fuel cell for long backup.

Generation blocks - Solar PV. 250 to 750 kW on roofs, deck rails, and a floating raft in the lee. Rapid shutdown and salt-fog connectors.

- Wind. Pier-mounted VAWTs at 5 to 20 kW each, plus one 200 to 500 kW HAWT on a nearby monopile where loads and setbacks allow.

- Wave. Point absorbers or oscillating units totaling 10 to 50 kW at start, rising with test results. Interface through quick-lift frames.

Controls - EMS priorities: safety, cold chain, hatchery, then processing. Heat pumps feed dryers and space heat with a glycol loop and thermal store.

6) Robotics and autonomy

- USV surveyor. ADCP, CTD, camera mast, route following, remote takeover.

- ROV inspector. 4K camera, sonar, manipulator for tags and line work.

- AUV mapper. CTD, fluorometer, side scan optional for seabed and habitat checks.

- Harvest assist. Cutters and winch PLCs with interlocks, e-stops, and light curtains.

- Docking and data. Wet-mate connectors under the pier and along the ship hull for charge and upload.

7) Hardware specification, minimum viable kits

A) Pier kit

- Frames and lines. 6 to 12 longlines on radial arms from piles, droppers at 1 to 2 meter spacing with quick release for storms.

- Bivalve racks. Mussel and oyster baskets on leeward faces for water polishing and food.

- Sensor buoys. Temperature, salinity, pH, dissolved oxygen, turbidity, chlorophyll or nutrients, current meters. 1 to 5 minute sampling over MQTT.

- Comms. 4G or 5G maritime, LoRaWAN for low bitrate, satellite backup.

- Processing spine. Dewatering, blanching, drying, milling, freezing, with inline spectroscopy for moisture and iodine and full HACCP traceability.

- Energy. 300 to 600 kW PV, 2 MWh battery, small VAWT row, 20 to 40 kW wave add-on, heat pump dryers.

B) Ship conversion kit

- Spaces. Hatchery and nursery in insulated decks, processing line in former cargo spaces, cold store, control room, and energy bay.

- Power. 400 to 800 kW PV across deck and canopy, 3 MWh battery, optional electrolyzer and fuel cell, shore power interface.

- Launch and recovery. USV cradle, ROV moonpool or side davit, AUV winch.

- Deck test bays. Standard DC and AC taps, fiber and Ethernet, safety e-stops, and lift points.

8) Data platform, “AquaOS”

- Pipelines. MQTT or Kafka, time series store for sensors, object store for imagery, PostGIS for sites and gear, feature store for ML.

- Models. Growth prediction, biofouling risk, harvest timing, quality prediction, and logistics planning.

- Apps. Farm Ops, Hatchery Ops, Processing QA, Sales and Offtake, Compliance, and MRV for carbon and nitrogen.

9) MRV, KPIs, and targets

- Productivity. Yield per line and per hectare, survival, harvest quality. Base plan 120 t wet per hectare for sugar kelp in temperate waters.

- Economics. Cost per harvested kilogram, uptime, unit margins by product, cash cycle days, contracted volume coverage.

- Ecosystem services. Carbon and nitrogen accounting with transparent factors, biodiversity on reef modules, water clarity trends, and contaminant logs.

- Energy. MWh per day by source, battery round-trip efficiency, curtailment hours, dryer kWh per kilogram of water removed.

10) Regulatory and stakeholder path

- Permissions. Align aquaculture and processing licences, navigation notices, and environmental permits. Build compliance into workflows from the start.

- Engagement. Fishers, councils, insurers, and port authorities. Track consultations and navigation risk reviews.

11) Risks and mitigations

- Storm and corrosion. Exposure-graded gear, quick-release droppers, sacrificial anodes, scheduled inspections.

- Biosecurity. Native species, seasonal calendars, processing QA for iodine and contaminants.

- Power quality. Hybrid inverters with fast ride-through, harmonic limits, and black start drills.

- Regulatory delay. Stage pilots in friendly jurisdictions first, with permit workflow software and clear MRV.

12) Pilot blueprints

A) Urban pier, 12-month pilot

- Layout. 8 longlines, 2 bivalve racks, 1 floating wetland, 2 sensor buoys, ROV davit, USV cradle, 300 kW PV, 1.5 MWh battery, one 20 kW wave unit, heat pump dryer, small hatchery, blanch and freeze line.

- Throughput. 80 to 160 tonnes wet kelp per season depending on site, plus bivalve output.

- Plan. Months 0 to 3 surveys and permits. Months 3 to 6 install and seed. Months 6 to 9 patrols and QA. Months 9 to 12 harvest, MRV, EBITDA review.

B) Ship-as-hub, 12-month pilot

- Layout. Ship moored to pier. Onboard nursery, processing, 400 kW PV, 3 MWh battery, electrolyzer option, USV and ROV stations, two deck test bays for wave or tidal prototypes.

- Role. Service a 10 to 30 hectare near-shore farm cluster. Provide cold chain and QA. Run vendor trials with witnessed test reports.

13) Novel opportunities unlocked

- Device proving ground. Standardized test bays and data formats shorten certification for wave, tidal, and coatings vendors. Sell berth fees and data services.

- Nutrient removal credits. Verified nitrogen removal near outfalls using sensor logs and harvest records.

- Community revenue. Lease micro-plots to local fishers for bivalves and kelp with shared processing and sales.

- Data products. Anonymized time series for yield, fouling, and device availability. Package into AquaOS subscriptions.

- Ship and pier networks. Link several sites into a regional platform that spreads processing capex and uses the ship to seed and harvest on a schedule.

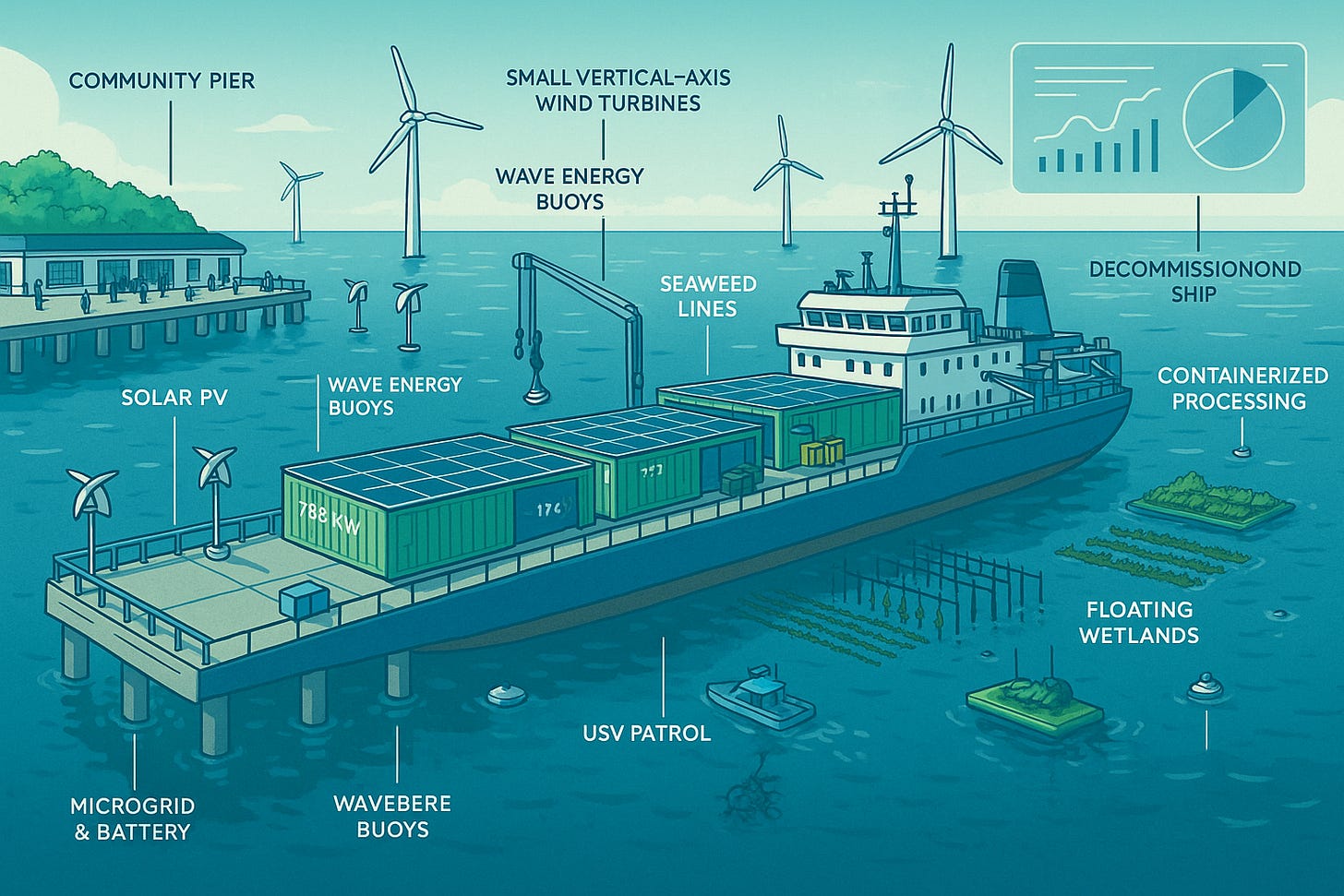

14) What it looks like

From the promenade you see a clean pier with PV rails, a row of small wind turbines, and a compact processing shed. Lines of kelp and bivalve baskets hang in clear grids, with floating wetlands near the outfall. A decommissioned ship sits alongside as the hub. Inside, a dashboard shows energy flow, biomass forecasts, weather windows, QA batches, and MRV results in one view. USVs run transects. An ROV checks lines and tags wear points.

Conclusion

Abandoned piers and decommissioned ships can do real work. With the kits and operating model in this blueprint, each site can produce food, restore habitat, and clean local waters while running on solar, wind, and wave power. The plan defines clear site types, minimum hardware for pier and ship conversions, an AquaOS data stack, and a 12 month pilot that proves both biology and business.

You have concrete targets to steer by. Plan for 3 to 6 MWh per day across hatchery, pumps, dryers, cold chain, robotics, and IT, backed by a DC backbone, grid forming inverters, and a 2 to 4 MWh battery. Aim for a base yield of about 120 tonnes wet per hectare for sugar kelp in temperate waters, with a first season throughput of 80 to 160 tonnes at an urban pier pilot. Track dryer kWh per kilogram of water removed and battery round trip efficiency to keep energy cost in check.

Execution is straightforward if you stage it. Select one urban pier and one ship hub. Run a 90 day baseline of currents, fouling, and water quality. Install longlines, bivalve racks, and floating wetlands, then bring up the processing spine and microgrid. Wire sensors, imaging, and robotics into AquaOS so farm ops, energy, QA, and compliance live on one screen. Lock two offtakes before the first harvest.

Measure what matters. Yield per line and hectare. Cost per harvested kilogram. Energy by source and dryer intensity. Verified nitrogen removal and biodiversity lift on reef and wetland modules. Uptime and safety. If these hit plan, link sites into a small regional network, share processing, and open paid test bays for wave and tidal devices. That gives you durable revenues from products, services, and data, plus a visible ecological gain at the waterfront.